基于Infineon公司的XMC44003 kW 双相LLC电源解决方案

325

325

拍明

拍明

原标题:Infineon XMC44003 kW 双相LLC电源解决方案

infineon公司的XMC4400是采用32位ARM Cortex-M4 CPU的XMC4000系列微控制器,集成了16KB引导ROM,16KB高速程序存储器,32KB高速数据存储器,32KB高速通信存储器和512KB闪存和4KB指令缓冲以及通信外设,模拟前端外设和工业控制外设等,主要用在工业连接,工业控制,电源转换,传感和控制等.本文介绍了XMC4400主要特性和系统框图,以及采用600 V CoolMOS™ C7和XMC4400的3 kW 双相LLC评估板主要特性和电指标,框图,电路图.

The XMC4400 devices are members of the XMC4000 Family of microcontrollers based on the ARM Cortex-M4 processor core. The XMC4000 is a family of high performanceand energy efficient microcontrollers optimized for Industrial Connectivity, IndustrialControl, Power Conversion, Sense& Control.

XMC4400主要特性:

CPU Subsystem

• CPU Core

– High Performance 32-bit ARM Cortex-M4 CPU

– 16-bit and 32-bit Thumb2 instruction set

– DSP/MAC instructions

– System timer (SysTick) for Operating System support

• Floating Point Unit

• Memory Protection Unit

• Nested Vectored Interrupt Controller

• One General Purpose DMA with up-to 8 channels

• Event Request Unit (ERU) for programmable processing of external and internalservice requests

• Flexible CRC Engine (FCE) for multiple bit error detection

On-Chip Memories

• 16 KB on-chip boot ROM

• 16 KB on-chip high-speed program memory

• 32 KB on-chip high speed data memory

• 32 KB on-chip high-speed communication memory

• 512 KB on-chip Flash Memory with 4 KB instruction cache

Communication Peripherals

• Ethernet MAC module capable of 10/100 Mbit/s transfer rates

• Universal Serial Bus, USB 2.0 host, Full-Speed OTG, with integrated PHY

• Controller Area Network interface (MultiCAN), Full-CAN/Basic-CAN with two nodes,64 message objects (MO), data rate up to 1MBit/s

• Four Universal Serial Interface Channels (USIC), providing four serial channels,usable as UART, double-SPI, quad-SPI, IIC, IIS and LIN interfaces

• LED and Touch-Sense Controller (LEDTS) for Human-Machine interface

Analog Frontend Peripherals

• Four Analog-Digital Converters (VADC) of 12-bit resolution, 8 channels each, with

input out-of-range comparators

• Delta Sigma Demodulator with four channels, digital input stage for A/D signalconversion

• Digital-Analog Converter (DAC) with two channels of 12-bit resolution

Industrial Control Peripherals

• Two Capture/Compare Units 8 (CCU8) for motor control and power conversion

• Four Capture/Compare Units 4 (CCU4) for use as general purpose timers

• Four High Resoultion PWM (HRPWM) channels

• Two Position Interfaces (POSIF) for servo motor positioning

• Window Watchdog Timer (WDT) for safety sensitive applications

• Die Temperature Sensor (DTS)

• Real Time Clock module with alarm support

• System Control Unit (SCU) for system configuration and control

Input/Output Lines

• Programmable port driver control module (PORTS)

• Individual bit addressability

• Tri-stated in input mode

• Push/pull or open drain output mode

• Boundary scan test support over JTAG interface

On-Chip Debug Support

• Full support for debug features: 8 breakpoints, CoreSight, trace

• Various interfaces: ARM-JTAG, SWD, single wire trace

XMC4400应用:

Motor Control

Position Detection

IO Devices

HMI

Solar Inverters

SMPS

Sense & Control

PLC

UPS

Light Networks

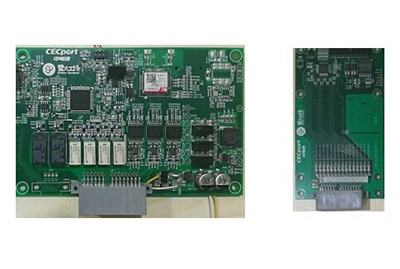

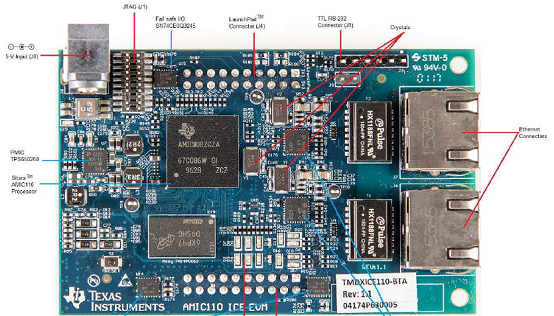

图1.XMC4400系统框图

图2.XMC4400电源连接图

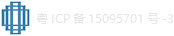

采用600 V CoolMOS™ C7和XMC4400的3 kW 双相LLC评估板

This document describes the design and performance of a 3 kW dual-phase LLC evaluation board intended for use in the isolated HV DC-DC stage of a Switch Mode Power Supply (SMPS) for telecom and industrial applications.

This is a high performance example with a complete Infineon solution, including HV and LV power MOSFETs, controllers, and drivers, demonstrating a very effective way to design the HV DC-DC stage of a telecom rectifier or Industrial SMPS fulfilling the highest standard of efficiency and reliability. The additional benefit of a very flat efficiency plot is also achieved through a mix of proper control techniques and best-in class power device selection.

Key Infineon products used to achieve this performance level include:

600 V CoolMOS™ C7 superjunction MOSFET

Isolated gate driver 1EDI60N12AF

SyncRec MOSFETs OptiMOS™ BSC093N15NS5

Advanced dual channel gate driver 2EDN7524

XMC4400 microcontroller

Bias QR flyback controller ICE2QR2280Z

As well as design information and documentation of the LLC converter, the reader will receive additional information on how the 600 V CoolMOS™ C7 behaves in LLC applications and the associated benefits, how the high performance magnetics design can be approached, and insights on how to develop dual-phase LLC converters in similar power ranges adapted to specific requirements.

The combined trends of continuous reduction of volume and size of the power converters and increase of required output power represent a serious challenge in modern Switch Mode Power Supply (SMPS) designs.

When addressing the high power density requirement, even in a SMPS with high peak efficiency, a typical problem consists in getting rid of the heat generated, especially at the full load, in the limited volume available.

A very powerful fan can help, but there may be a lot of side effects, like the acoustic noise or the generated vibration, which may be not tolerated by other system components, like e.g. hard disk drives in computing applications. And in any case the effectiveness of the forced ventilation is linked to the air impedance inside the SMPS. Unfortunately, a typical consequence of the power density increase is the increase of the air impedance inside the Power Supply Unit (PSU). Especially in industrial and telecom applications, there are cases where the fan is even not allowed.

The best solution is to try to limit the heat generated especially in the most critical condition from thermal perspective, the full load operation. This means that having a very high peak efficiency (typically achieved at 50% load) may not be enough on the purpose, but the same high efficiency has to be extended up to full load operation.

In order words, this requirement involves the need of a very flat efficiency plot, at least from 40-50% up to 100% load. On the other hand, in N+1 redundant application the percentage of SMPS operation near full load is relatively lower compared to the one below half load, making for this reason also important the efficiency down to around 30% load.

The combination of these typical performance requirements of industrial and telecom high power SMPS can be fulfilled through a very flat efficiency plot from 30% to 100% load.

Similar curve is not compatible with the natural behavior of a power converter, whose efficiency plot has typically the shape of a parabola with the peak at around mid load. In other words, the desired “flatness” can be achieved only through a dedicated power converter design, which involves a proper selection of the topologies, power devices, magnetic components and control techniques.

One of the most popular solutions adopted in power conversion in order to achieve this goal is the Multiphase approach. Scaling and balancing are two typical aspects of this design technique.

In this document the fundamental aspects of a multiphase LLC converter are analyzed, giving an overview about the most important design choices, especially in power semiconductors and control techniques.

A practical example is provided thorugh the description of a 3 kW dual-phase LLC demo board totally designed with Infineon power semiconductors and IC components. In this document it is demonstrated that the usage of state-of-art high and medium voltage silicon MOSFETs, in combination with optimized driving and sophisticated digital control allows fulfilling all the most important requirements of a modern high power SMPS, both in term of perfomance and reliability.

Main requirements in the technical specification

Input voltage range 350-410 Vdc

Nominal input voltage 380 Vdc

Output voltage 44 V – 58 V ±1%

Nominal output voltage 54 Vdc

Max output current / power 55 A/3000 W

dual-phase approach

Power density >30 W/inch³

Efficiency target: 10/50/100% Pmax=95%/98%/97.5%

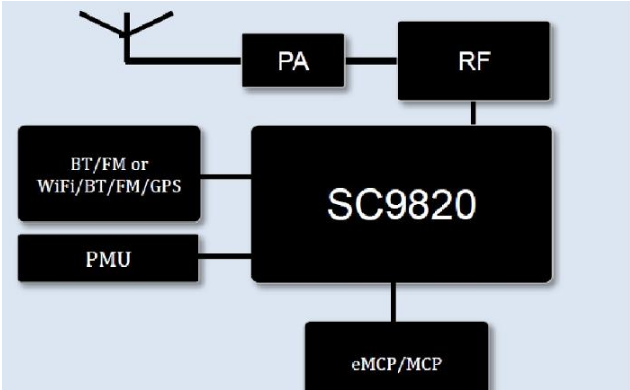

图3.3 kW 双相LLC评估板基本概念

图4.3 kW 双相LLC评估板外形图

详情请见:

![]() Infineon-XMC4400-DS-v01_02-EN.pdf

Infineon-XMC4400-DS-v01_02-EN.pdf

![]() Infineon-ApplicationNote_Evaluationboard_3kW_dual_phase_LLC-AN-v01_00-EN.pdf

Infineon-ApplicationNote_Evaluationboard_3kW_dual_phase_LLC-AN-v01_00-EN.pdf

责任编辑:HanFeng

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)