Infineon CoolMOS C7第五代PWM控制器的800W Platinum服务器电源设计方案

1474

1474

拍明

拍明

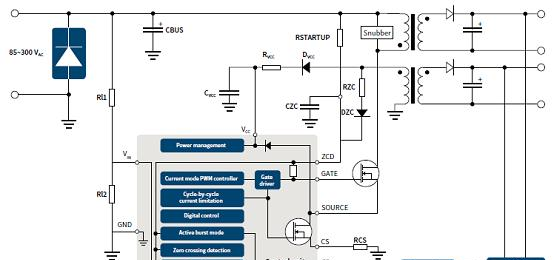

Infineon公司的600VCoolMOS™ C7是第五代PWM控制器,具有超低开关损耗,集成了700V和800V超结MOSFET,具有成套保护特性如输入OVP,输入欠压保护(brown in/out),引脚对GND和OTP延迟.此外还具有自动重起恢复功能,以最小化系统中断工作,主要用在服务器,电信,太阳能和工业应用.本文介绍了600 V CoolMOS™ C7主要特性和优势, 60W隔离反激SMPS应用电路以及采用600 V CoolMOS™ C7和XMC数控的800W Platinum®服务器电源主要特性和框图,主板和控制板电路图和材料清单.

The 600 V CoolMOS™ C7 series of devices offers a ~50% reduction in turn-off losses compared to the CoolMOS™ CP, offering a GaN-like level of performance in PFC, TTF and other hard-switching topologies. The CoolMOS™ C7 delivers an area-specific on-resistance (RDS(ON)*A) of just 1Ω per mm2, extending Infineon’s portfolio of products with lowest RDS(ON) per package to support customer efforts to further increase power density.

The 600 V CoolMOS C7 series features ultra-low switching losses and targets high-power SMPS applications such as server, telecom, solar and industrial applications requiring high efficiency and a reduced Bill of Materials (BOM) as well as low Total Cost of Ownership (TCO).

Applications driven by efficiency and TCO, such as hyper-scale data centers and telecom base stations, benefit from the switching loss reduction offered by CoolMOS C7. Efficiency gains of 0.3% to 0.7% in PFC and 0.1% in LLC topologies can be achieved, leading to significant TCO benefits. In the case of a 2.5 kW server PSU, for example, using 600 V C7 MOSFETs can result in energy cost reductions of ~10% for PSU energy loss.

In BOM and cost-driven designs such as enterprise servers, the 600 V CoolMOS™ C7 devices offer a cost reduction in magnetics. Due to the significantly lower gate charge and output capacitance, the C7 can be operated at double the normal switching frequencies with only a marginal loss in efficiency. This allows the size of magnetic components to be minimized, lowering the overall BOM cost. For example, doubling the switching frequency from 65 kHz to 130 kHz may reduce the magnetic component cost by as much as 30%.Rapid start-up with cascode configuration

To achieve fast start-up performance, 5th generation controller utilize the high voltage MOSFET together with an internal current regulator to operate the start-up sequence in a safe and rapid manner, which is commonly known as cascode configuration.Upsized zero crossing counters for valley detection With the implementation of 10 zero crossing counters, the ability to detect AC line input level and an intelligent adaptive digital algorithm (patent pending), it enabled the5th generation controller to minimize the spread of switching frequency under differentAC line input conditions. This innovative approach has enabled SMPS designers to designwith higher switching frequency to take advantage of smaller magnetics and lowering ofsystem BOM cost.

Run cooler with CoolMOSTM P7 family In tandem with Infineon’s leadership in the area of high voltage superjunction MOSFETs,the latest 700 V and 800 V CoolMOS™ P7 families will be integrated together with the 5th generation controller in a single package.CoolSETTM is available in both through-holeand SMD packages and thereby eliminates the need of heatsink and reduces BOM countwith a small footprint.

Comprehensive suite of protection features In addition to the typical output protection such as output short, overload and overvoltage protection, the 5th generation controller is incorporating additional protections todetect abnormal line input conditions such as over-voltage and under-voltage protection.

Similarly, in-system-protection has been further enhanced with the introduction ofVCC and CS pin short to ground to prevent controller damage during abnormal start-upconditions and OTP has been enhanced with hysteresis to improve operational faulthandling. To minimize interruption to system operation, all protection modes areimplemented with auto resume to enhance user experience.

600 V CoolMOS™ C7主要特性:

››Integrated 700 V and 800 Vsuperjunction MOSFET withavalanche capability

››Comprehensive suite of protectionwhich include input OVP, brownin/out, pin short to GND and OTPwith hysteresis

››Innovative quasi-resonant switchingscheme to minimize frequencyspread under different line inputconditions

600 V CoolMOS™ C7主要优势:

››High efficiency with latestCoolMOSTM P7 family andquasi-resonant switching scheme

››Auto-restart recovery scheme tominimize interruption to systemoperation

››Extensive protection coverage toincrease system robustness

››Rapid start-up performance withcascode configuration

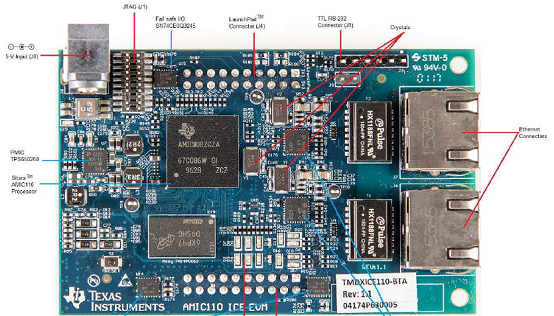

图1.60W隔离反激SMPS应用电路

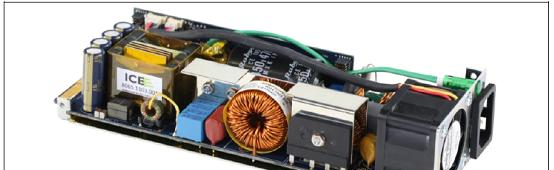

采用600 V CoolMOS™ C7和XMC数控的800W Platinum®服务器电源

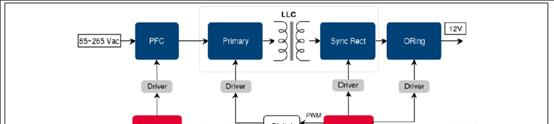

This document introduces a complete Infineon system solution for an 800 W server power supply, which achieves the 80Plus® Platinum® standard. The power supply is composed of a Continuous Conduction Mode (CCM) Power Factor Correction (PFC) converter and a half-bridge LLC DC-DC converter. This document focuses on the necessary microcontroller configuration and the implemented control for adequate system performance, which is demonstrated with test results.

The Infineon components used in the 800 W server power supply are:

600 V CoolMOS™ C7 superjunction MOSFET in TO-247 4-pin and TO-220 packages as well as 650 V CoolSiC™ Schottky diode Gen5

40 V and 25 V OptiMOS™ 5 MOSFETs

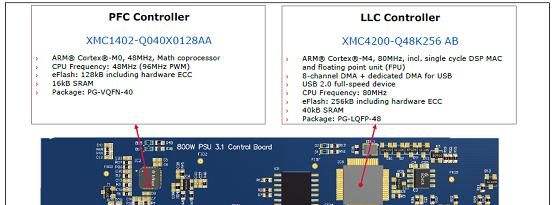

1EDI20N12AF isolated and 2EDN7524F non-isolated gate drivers (EiceDRIVER™) XMC1402 and XMC4200 microcontrollers

ICE2QR2280G CoolSET™ QR flyback controller

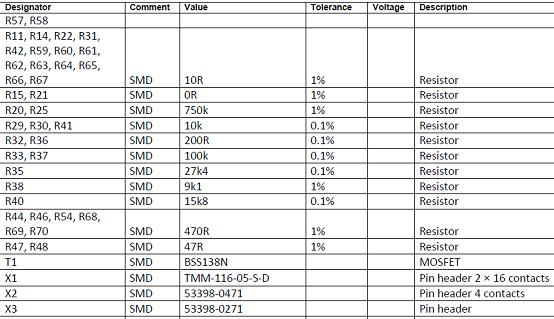

图2.800W Platinum®服务器电源外形图

The 600 V CoolMOS™ C7 MOSFET technology in soft-switching topologies like the LLC working at a resonant frequency around 150 kHz

The isolated and the non-isolated gate drivers from the EiceDRIVER™ IC family

The flexibility and performance power of the XMCTM microcontrollers for server power supplies

800W Platinum®服务器电源主要特性:

Attractive compact design in 30 W/in3 form factor

Efficiency that outperforms the Platinum® efficiency standard throughout the entire load demand at both 115 V AC and 230 V AC, as shown in Performance and steady-state operation Figure 41 in section 6.1

Low Total Harmonic Distortion (THD) and high PF response, as shown in Figure 42 and Figure 43 respectively, from 20% of the load

Fully digital control implementation in both the PFC boost converter using XMC1400, as described in the Power factor correction stage section, and the LLC resonant converter using the XMC4200, as described in the LLC resonant DC-DC converter section

High performance achieved by using Infineon Technologies best-in-class devices:

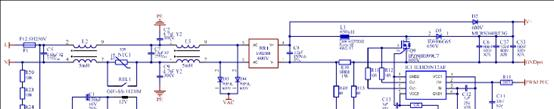

o Single TO-247 4-pin 600 V CoolMOSTM C7 SJ MOSFET in the PFC boost converter, along with a single TO-220 650 V CoolSiCTMschottky diode Gen5

o TO-220 600 V CoolMOSTM C7 SJ MOSFET on the primary side of the LLC resonant converter and OptiMOSTM 5 40 V and 25 V as Synchronous Rectification (SR) and ORing MOSFETs, respectively

oEiceDRIVERTM 1EDI isolated and EiceDRIVERTM 2EDN non-isolated gate driver ICs

o QR flyback controller ICE2QR2280G CoolSET™

Robust and realiable operation under different abnormal conditions:

o Smooth inrush current during start-up as shown in Figure 46

o Power Line Disturbance (PLD) events, like AC Line Drop Out (ACLDO) as described in Table 8, as well as voltage sags as describes in Table 9

o Brownout reaction .

o Load-step reponse at different abrupt load changes.

o Over Current (OC) condition reaction as described in the Over Current Protection (OCP) section, as well as the response of the PSU in case of a short-circuit event.

Fully compliant with both peak and average Class B conducted EMI EN 55022 standard limits.

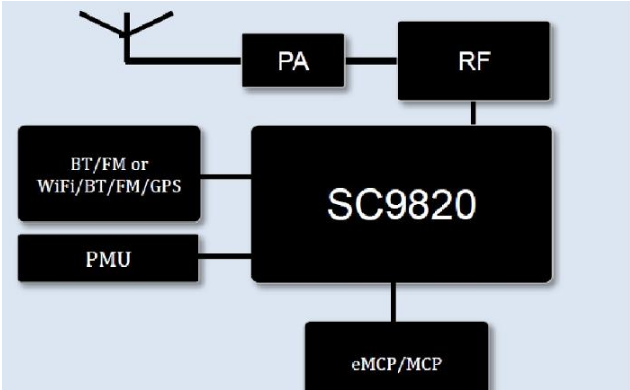

图3.800W Platinum®服务器电源框图

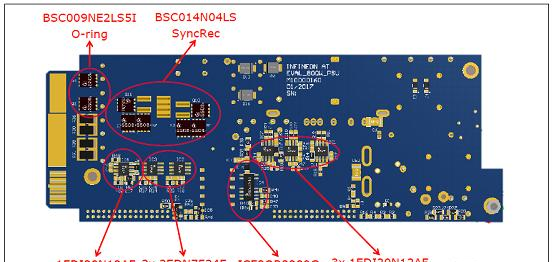

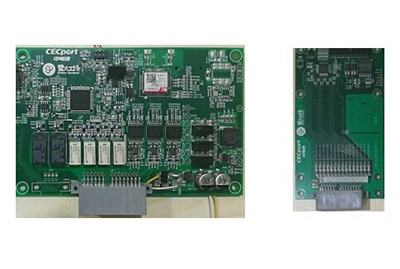

图4.800W Platinum®服务器电源的功能布局图(正面)

图5.800W Platinum®服务器电源的元件布局图(背面)

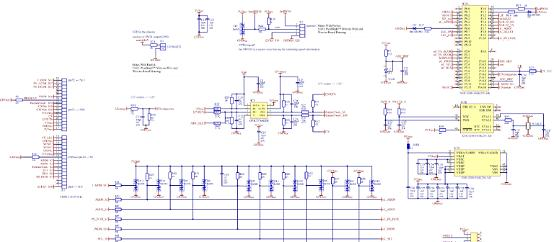

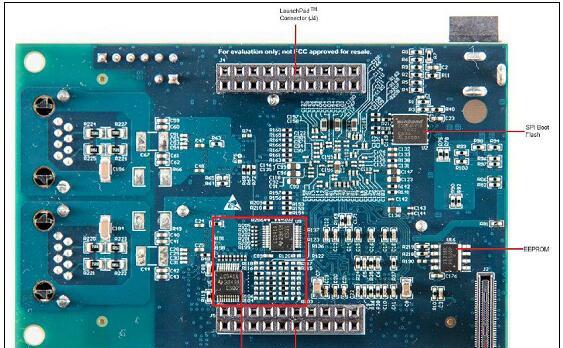

图6.800W Platinum®服务器电源控制板和XMC MCU主要特性图

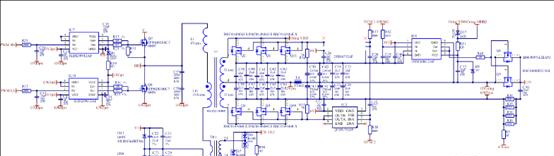

图7.800W Platinum®服务器电源主板电路图:PFC级电路图

图8.800W Platinum®服务器电源主板电路图:LLC级电路图

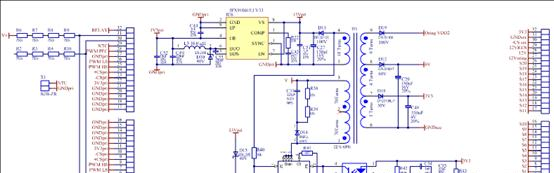

图9.800W Platinum®服务器电源主板电路图:辅助电源,包括控制板和NTC温度传感器连接器

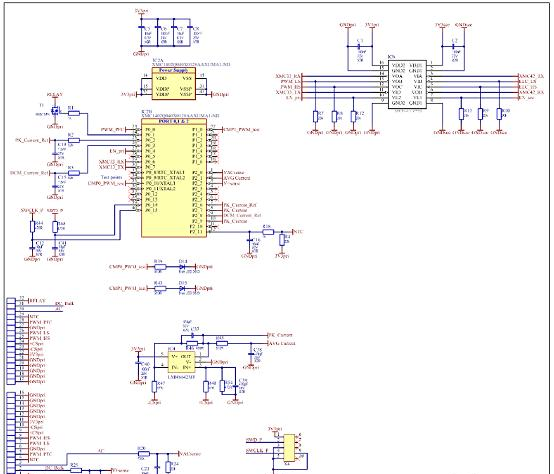

图10.800W Platinum®服务器电源控制板电路图:初级边控制器(XMC1402)

图10.800W Platinum®服务器电源控制板电路图:次级边控制器(XMC4200)

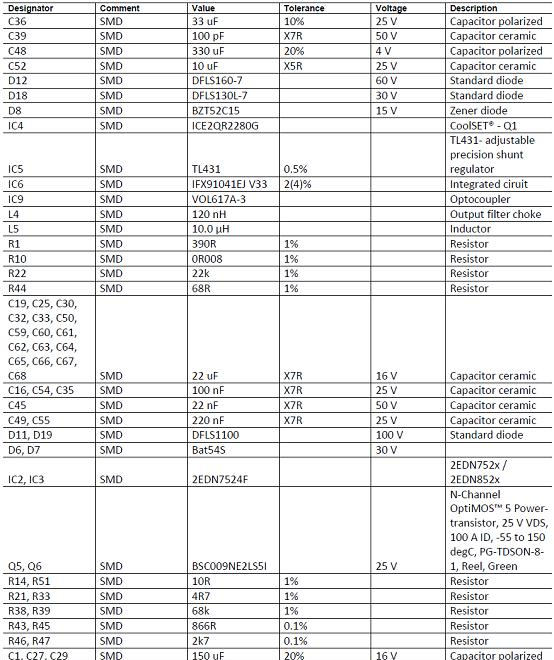

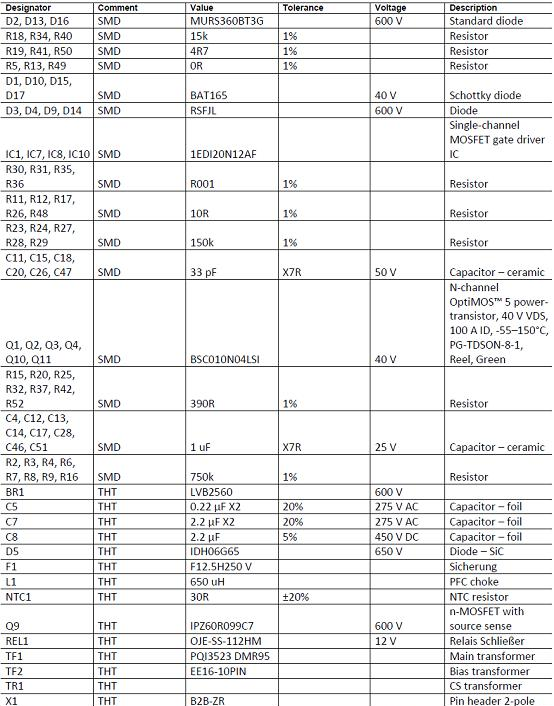

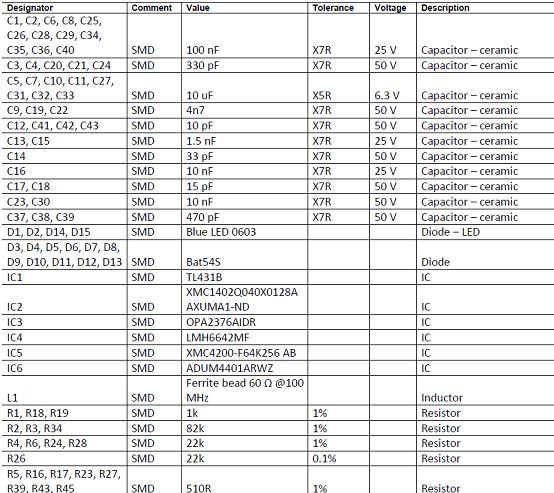

主板材料清单(BOM):

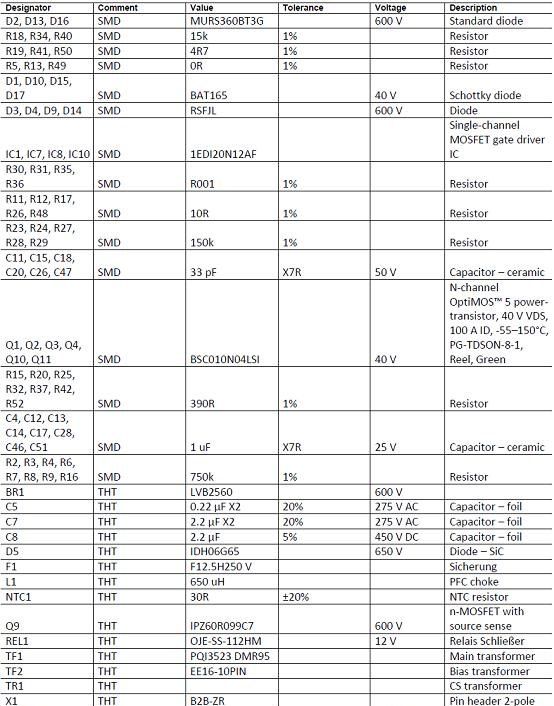

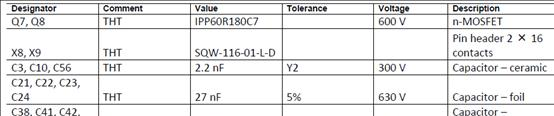

控制板材料清单(BOM):

Infineon英飞凌科技介绍

Infineon公司是全球十大半导体制造商之一。1999年5月1日,西门子半导体公司正式更名为Infineon,总部设在德国慕尼黑。主要生产汽车和工业电子芯片、保密及IC卡应用IC、通讯多媒体芯片、存储器件等。1998年Infineon公司是全球十大半导体制造商之一。该公司在全球亚、欧、美三大洲5个国家拥有10个制造工厂,在九个国家设有16个研发中心,1998年员工约25,000人,主要合作伙伴有Motorola、IBM、MoselVitelic等。

英飞凌科技公司于1999年4月1日在德国慕尼黑正式成立,是全球领先的半导体公司之一。其前身是西门子集团的半导体部门,于1999年独立,2000年上市。其中文名称为亿恒科技,2002年后更名为英飞凌科技。

总部位于德国Neubiberg的英飞凌科技股份公司,为现代社会的三大科技挑战领域——高能效、移动性和安全性提供半导体和系统解决方案。

Infineon 英飞凌专注于迎接现代社会的三大科技挑战: 高能效、 移动性和 安全性,为汽车和工业功率器件、芯片卡和安全应用提供半导体和系统解决方案。英飞凌的产品素以高可靠性、卓越质量和创新性著称,并在模拟和混合信号、射频、功率以及嵌入式控制装置领域掌握尖端技术。英飞凌的业务遍及全球,在美国加州苗必达、亚太地区的新加坡和日本东京等地拥有分支机构。2012财年(截止到2012年9月份),公司实现销售额39亿欧元。

在中国

西门子半导体事业部作为英飞凌科技(中国)有限公司的前身于1995年正式进入中国市场。自从1996年在无锡建立第一家企业以来,英飞凌的业务取得非常迅速的增长,目前在中国已经拥有8家公司和1700多名员工。2004年英飞凌在中国的销售额增加了30%,高于中国半导体行业的平均增长速度,在国内的排名由2002年的第七位上升至前四位,成为英飞凌亚太乃至全球业务发展的一个重要推动力。

进入中国以来,英飞凌不断顺应客户与市场的需求,研发及生产一系列能够应用于本地市场的产品。目前,英飞凌先进的半导体解决方案已广泛应用于各个领域,同时我们凭借雄厚的技术实力和全球领先的经验,与包括联想、华为、方正、红丰、握奇等国内领先厂商展开深入合作,为中国电子行业的腾飞做出应有的贡献。

英飞凌在中国的协议投资额已逾10亿美元,建立了涵盖研发、生产、销售市场、技术支持等在内的完整的产业链。在研发方面,英飞凌在上海、西安建立了研发中心,利用国内的人才资源,参与全球的重点项目研究;在无锡、苏州的后道生产工厂,为中国及全球其他市场生产先进的芯片产品;并以北京、上海、深圳和香港为中心在国内建立了全面的销售网络。同时,我们在销售、产品代工、技术研发、人才培养等方面与国内领先的企业、高等院校开展了深入的合作,与中芯国际等领先的电子代工企业进行生产制造方面的合作。到2007年,英飞凌计划将在华累计投资增加到12亿美元,员工成长到3000名。

公司秉承扎根中国的承诺,致力于和政府及科研机构携手开发行业标准,支持中国集成电路产业增强竞争力。公司与国内领先高校合作建立实验室,进行汽车电子、智能卡等方面的研发合作,现在进行的项目有上海同济大学汽车电子实验室、天津大学内燃机实验室等。公司每年专门拨出几十万元,在复旦大学、西安电子科技大学、同济大学等众多领先高校设立奖学金,培养优秀的技术和管理人才,并为其提供施展才华的广阔空间。

作为优秀的企业公民,英飞凌致力于回馈社会,协助中国实现可持续发展。公司积极开展资助贫困儿童入学的活动,一方面号召英飞凌在国内的员工捐款捐物,帮助贫困地区的儿童返回校园;另一方面派员工到贫困地区提供义务教学,为中国基础教育的发展做出贡献。此外,英飞凌还与西安考古研究所积极合作,利用公司及员工的捐款,资助该研究所的文物修复工作。

中国在英飞凌的全球战略中具有举足轻重的地位,公司在过去的发展历程中,见证了中国改革开放取得的巨大成就。放眼未来,公司愿与中国在核心层面进行密切合作,与快速成长的中国集成电路产业共同发展,与中国共创辉煌!

责任编辑:Davia

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)