TI TMS320F28379数控500W转换器参考设计TIDM-1001

398

398

拍明

拍明

原标题:TI TMS320F28379数控500W转换器参考设计TIDM-1001

TI公司的TMS320F28379是功能强大的32位浮点微控制器(MCU),支持新双核C28x架构,大大提升了系统性能,每核信号处理性能200MHz,集成模拟和控制外设使高端系统的设计者合并控制体系结构,不需要多个处理器;器件还集成了512KB (256KW)或1MB (512KW)闪存(ECC保护), 172KB (86KW)或204KB (102KW) RAM(ECC保护或奇偶校验位保护),支持第三方开发的双区安全以及唯一识别号码.满足汽车应用的AEC Q100规范,主要用在先进驾驶辅助系统(ADAS),建筑物自动化,POS终端,EV/HEV动力传动,工厂自动化,电网架构,工业传输,医疗,健康和健美设备,马达驱动,供电,通信设备,测试和测量.本文介绍了TMS320F28379主要特性,框图,以及采用C2000™微控制器的数控500W两相交叉LLC谐振转换器参考设计TIDM-1001主要特性和指标,电路图和材料清单.

The Delfino™ TMS320F2837xD is a powerful 32-bit floating-point microcontroller unit (MCU) designed for advanced closed-loop control applications such as industrial drives and servo motor control; solar inverters and converters; digital power; transportation; and power line communications. Complete development packages for digital power and industrial drives are available as part of the powerSUITE and DesignDRIVE initiatives. While the Delfino product line is not new to the TMS320C2000™ portfolio, the F2837xD supports a new dual-core C28x architecture that significantly boosts system performance. The integrated analog and control peripherals also let designers consolidate control architectures and eliminate multiprocessor use in high-end systems.

The dual real-time control subsystems are based on TI’s 32-bit C28x floating-point CPUs, which provide 200 MHz of signal processing performance in each core. The C28x CPUs are further boosted by the new TMU accelerator, which enables fast execution of algorithms with trigonometric operations common in transforms and torque loop calculations; and the VCU accelerator, which reduces the time for complex math operations common in encoded applications.

The F2837xD microcontroller family features two CLA real-time control coprocessors. The CLA is an independent 32-bit floating-point processor that runs at the same speed as the main CPU. The CLA responds to peripheral triggers and executes code concurrently with the main C28x CPU. This parallel processing capability can effectively double the computational performance of a real-time control system.

By using the CLA to service time-critical functions, the main C28x CPU is free to perform other tasks, such as communications and diagnostics. The dual C28x+CLA architecture enables intelligent partitioning between various system tasks. For example, one C28x+CLA core can be used to track speed and position, while the other C28x+CLA core can be used to control torque and current loops.

The TMS320F2837xD supports up to 1MB (512KW) of onboard flash memory with error correction code (ECC) and up to 204KB (102KW) of SRAM. Two 128-bit secure zones are also available on each CPU for code protection.

Performance analog and control peripherals are also integrated on the F2837xD MCU to further enable system consolidation. Four independent 16-bit ADCs provide precise and efficient management of multiple analog signals, which ultimately boosts system throughput. The new sigma-delta filter module (SDFM) works in conjunction with the sigma-delta modulator to enable isolated current shunt measurements. The Comparator Subsystem (CMPSS) with windowed comparators allows for protection of power stages when current limit conditions are exceeded or not met. Other analog and control peripherals include DACs, PWMs, eCAPs, eQEPs, and other peripherals.

Peripherals such as EMIFs, CAN modules (ISO 11898-1/CAN 2.0B-compliant), and a new uPP interface extend the connectivity of the F2837xD. The uPP interface is a new feature of the C2000™ MCUs and supports high-speed parallel connection to FPGAs or other processors with similar uPP interfaces. Lastly, a USB 2.0 port with MAC and PHY lets users easily add universal serial bus (USB) connectivity to their application.

TMS320F28379主要特性:

• Dual-Core Architecture

– Two TMS320C28x 32-Bit CPUs

– 200 MHz

– IEEE 754 Single-Precision Floating-Point Unit (FPU)

– Trigonometric Math Unit (TMU)

– Viterbi/Complex Math Unit (VCU-II)

• Two Programmable Control Law Accelerators (CLAs)

– 200 MHz

– IEEE 754 Single-Precision Floating-Point Instructions

– Executes Code Independently of Main CPU

• On-Chip Memory

– 512KB (256KW) or 1MB (512KW) of Flash (ECC-Protected)

– 172KB (86KW) or 204KB (102KW) of RAM (ECC-Protected or Parity-Protected)

– Dual-Zone Security Supporting Third-Party Development

– Unique Identification Number

• Clock and System Control

– Two Internal Zero-Pin 10-MHz Oscillators

– On-Chip Crystal Oscillator

– Windowed Watchdog Timer Module

– Missing Clock Detection Circuitry

• 1.2-V Core, 3.3-V I/O Design

• System Peripherals

– Two External Memory Interfaces (EMIFs) With ASRAM and SDRAM Support

– Dual 6-Channel Direct Memory Access (DMA) Controllers

– Up to 169 Individually Programmable, Multiplexed General-Purpose Input/Output (GPIO) Pins With Input Filtering

– Expanded Peripheral Interrupt Controller (ePIE)

– Multiple Low-Power Mode (LPM) Support With External Wakeup

• Communications Peripherals

– USB 2.0 (MAC + PHY)

– Support for 12-Pin 3.3 V-Compatible Universal Parallel Port (uPP) Interface

– Two Controller Area Network (CAN) Modules (Pin-Bootable)

– Three High-Speed (up to 50-MHz) SPI Ports (Pin-Bootable)

– Two Multichannel Buffered Serial Ports (McBSPs)

– Four Serial Communications Interfaces (SCI/UART) (Pin-Bootable)

– Two I2C Interfaces (Pin-Bootable)

• Analog Subsystem

– Up to Four Analog-to-Digital Converters (ADCs)

– 16-Bit Mode

– 1.1 MSPS Each (up to 4.4-MSPS System Throughput)

– Differential Inputs

– Up to 12 External Channels

– 12-Bit Mode

– 3.5 MSPS Each (up to 14-MSPS System Throughput)

– Single-Ended Inputs

– Up to 24 External Channels

– Single Sample-and-Hold (S/H) on Each ADC

– Hardware-Integrated Post-Processing of ADC Conversions

– Saturating Offset Calibration

– Error From Setpoint Calculation

– High, Low, and Zero-Crossing Compare, With Interrupt Capability

– Trigger-to-Sample Delay Capture

– Eight Windowed Comparators With 12-Bit Digital-to-Analog Converter (DAC) References

– Three 12-Bit Buffered DAC Outputs

• Enhanced Control Peripherals

– 24 Pulse Width Modulator (PWM) Channels With Enhanced Features

– 16 High-Resolution Pulse Width Modulator (HRPWM) Channels

– High Resolution on Both A and B Channels of 8 PWM Modules

– Dead-Band Support (on Both Standard and High Resolution)

– Six Enhanced Capture (eCAP) Modules

– Three Enhanced Quadrature Encoder Pulse (eQEP) Modules

– Eight Sigma-Delta Filter Module (SDFM) Input Channels, 2 Parallel Filters per Channel

– Standard SDFM Data Filtering

– Comparator Filter for Fast Action for Out of Range

• Configurable Logic Block (CLB)

– Augments Existing Peripheral Capability

– Supports Position Manager Solutions

• Package Options:

– Lead-Free, Green Packaging

– 337-Ball New Fine Pitch Ball Grid Array (nFBGA) [ZWT Suffix]

– 176-Pin PowerPAD™ Thermally Enhanced Low- Profile Quad Flatpack (HLQFP) [PTP Suffix]

– 100-Pin PowerPAD Thermally Enhanced Thin Quad Flatpack (HTQFP) [PZP Suffix]

• Temperature Options:

– T: –40ºC to 105ºC Junction

– S: –40ºC to 125ºC Junction

– Q: –40ºC to 125ºC Free-Air

(AEC Q100 Qualification for Automotive Applications)

TMS320F28379应用:

• Advanced Driver Assistance Systems (ADAS)

• Building Automation

• Electronic Point of Sale

• Electric Vehicle/Hybrid Electric Vehicle (EV/HEV) Powertrain

• Factory Automation

• Grid Infrastructure

• Industrial Transport

• Medical, Healthcare, and Fitness

• Motor Drives

• Power Delivery

• Telecom Infrastructure

• Test and Measurement

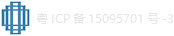

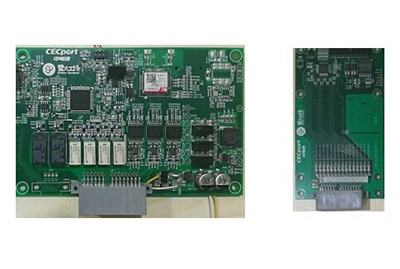

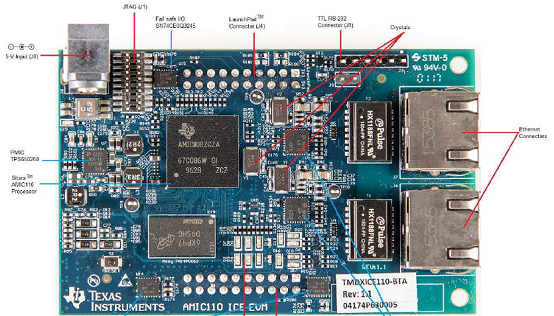

采用C2000™微控制器的数控500W两相交叉LLC谐振转换器参考设计TIDM-1001

This TI Design implements a digitally-controlled, 500-W, two-phase interleaved LLC resonant converter. The system is controlled by a single, C2000 microcontroller (MCU), MS320F28379, which also generates pulse width modulation (PWM) waveforms for all power electronic switching devices under all operating modes. This design implements an innovative current

sharing technique to accurately achieve current balancing between phases.

Resonant converters are popular DC-DC converters frequently used in server, telecom, automotive, industrial, and other power supply applications. The converters are a good choice for medium- to highpower applications because of their adherence to improving industry standards, ever-increasing powerdensity goals, and high-performance (efficiency, power density, and so forth) standards, These are variable-frequency converters where the PWM-switching frequency of operation frequently changes during runtime. For reliable operation the changing frequencies must not produce any glitches or irregular PWM behavior. For applications with high-output currents that require input-output isolation, it is a common practice to use synchronous rectification (SR) on the secondary of the isolation transformer. SR uses additional power electronic devices switching with changing frequencies. High-power applications may require use of multiphase interleaved converters. These interleaved converters have even more devices switching with variable frequencies and additionally require fixed-phase relationships between various phases under all operating frequencies. Guaranteeing correct PWM waveform generation with changing frequencies under all operating conditions is a big challenge for the controller. Furthermore, interleaving multiple phases of resonant converters presents current sharing challenges between phases.

Inadequate or improperly implemented current sharing or incorrect PWM waveform generation can lead to converter failure, significant system or component damage, and, in the worst case, significant property damage or resultant bodily injury or loss of life.

In server and telecom power supply applications, these converters are used to work as the isolated DCDC converter stage in the rectifier system. These converters provide high fficiency and power density through soft-switching, SR, and other techniques.

These converters are gaining popularity in automotive on-board charging applications. Additionally, these devices may be used as isolated, bi-directional converters in electric vehicles (EVs) and hybrid electric vehicle (HEVs).

This design implements a 500-W, two-phase, interleaved half-bridge (HB) LLC resonant converter with SR on the secondary. The system is controlled by a single C2000 MCU, TMS320F28379, which also generates correct PWM waveforms for all power electronic switching devices (MOSFETs) using the latest features on C2000 MCUs. An innovative current sharing technique is implemented by the C2000 MCU to accurately achieve current and phase balancing for multiphase interleaved converters.

The accompanying software allows programming the controller and experimenting with different control parameters to tune the control loop for good system performance. This design supports the use of C2000 powerSUITE tools like the compensation designer, the software frequency response analyzer, and the solution adapter. The software project allows users to evaluate the complete system with the help of these supported tools. This document provides the hardware and software design details along with the test results. This document also describes a structured step-by-step method to evaluate this solution by starting with a simple open-loop excitation and then working towards a complete well-tuned closed-loop system.

TMS320F28379主要特性:

• Digitally-Controlled Two-Phase Interleaved LLC Resonant DC-DC Converter

• 500-W (250 W per Phase) Full-Load Power or 42.5-A Full-Load Current

• Vin: 370-V to 410-V DC

• Vout: 12-V DC

• Resonant Frequency: 250 kHz, Switching Frequency Range: 200 kHz to 350 kHz

• Peak Efficiency: 94.5%, Efficiency > 90% for all Loads Above 10% of Rated Load

• Excellent Current Sharing Between Phases Without Any Additional Hardware

• Phase Shedding With Programmable Limits

• Fault Protection: Phase and Output Overcurrent, Output Overvoltage, and Input Undervoltage and Overvoltage

• Supported by Various C2000 powerSUITE Tools

TMS320F28379应用:

• Server Power Supplies

• Telecom Rectifiers

• Automotive Charging

• Industrial Power Supplies

图 500W转换器参考设计TIDM-1001外形图

500W转换器参考设计TIDM-1001主要性能指标:

参考设计TIDM-1001材料清单:

详情请见:

责任编辑:HanFeng

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)