基于C8051F9XX系列的超低功耗MCU医疗(红外测温仪)解决方案

385

385

拍明

拍明

应用领域:医疗健康

方案类型:原型方案

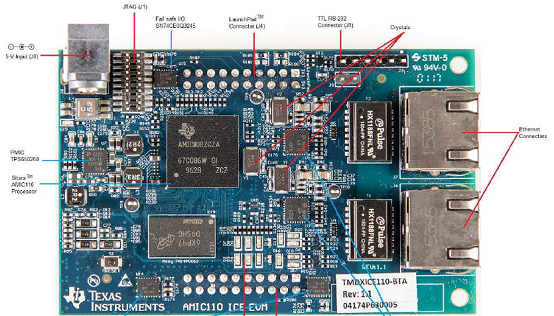

主控芯片:C8051F9XX

方案概述

体温是一个重要的生命参数,为医生提供了重要生理状态信息,因此对人体温度测量不仅可以确诊某些疾病的发生,还可以对隐藏于身体内部的健康隐患起着积极的预防和警示作用。 在进行体温监测时,主要有三个基本要求:非接触,测量的快速性,准确性。非接触红外体温检测技术用于人体温度的快速测量,产品需求量很大,国际国内中,精度高的测量仪器成本高,功耗大,不宜家庭使用所以研制价格低廉,功耗低的测量仪器非常必要。

C8051F9XX

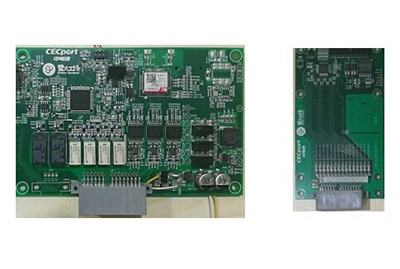

1. Introduction

The C8051F9xx family of low-voltage/low-power MCUs is an excellent choice for battery-powered embedded

systems. Following are some of the key features of this product family:

Low Active and Inactive Mode Current

150 µA/MHz, 160 µA/MHz, or 170 µA/MHz Active Mode Current @ 25 MHz

< 1 µA Sleep Mode Current

Fast Wakeup Time and Fast Code Execution

400 ns Suspend Mode Wakeup (using the low power internal oscillator)

2 µs Sleep Mode Wakeup (two-cell mode) or

10 µs Sleep Mode Wakeup (one-cell mode)

Up to 25 MIPs Operation

Fast ADC Acquisition Time

1.5 µs VREF turn-on time, occurs while ADC is tracking

3.3 µs back-to-back analog acquisition time

Support for 1 and 2 Cell Battery Configurations

0.9–1.8 V supply voltage range allows the system to be powered from a single alkaline or silver oxide battery.

1.8–3.6 V supply voltage range allows the system to be powered from a single lithium battery or two alkaline batteriesplaced in series.The C8051F9xx MCU family is very flexible and provides application software control over many factors affectingdevice power consumption. This application note describes how to achieve maximum efficiency in each powermode and how to optimize application code to take advantage of the low power features of the C8051F9xx family.Included with this application note is example software that can be used to place the C8051F9xx MCU into each ofits power modes for supply current measurements. Also included is a low-power software template that may beused as a starting point for new code development. The software can be found in the AN358SW.zip archive, whichis distributed with this application note.

2. Key Points

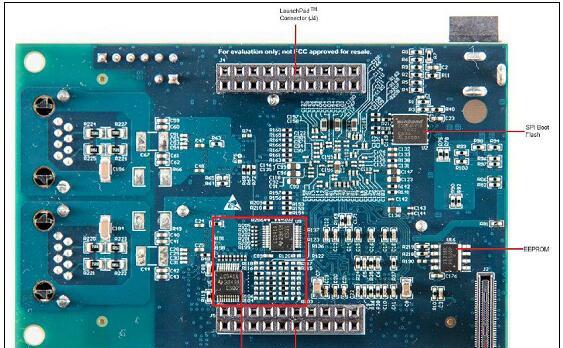

Two Regions of Operation—C8051F9xx devices have two distinct regions of operation. The Flash one-shotcircuit must be disabled (bypassed) for high system clocks and enabled for system clocks in order to minimizesupply current in the normal power mode. The optimumcrossover frequency is 10 MHz (C8051F93x/2x) or 14MHz (C8051F91x/0x/9x/8x).

Sleep Mode Supply Current—The current in Sleep mode should always be < 1 µA at room temperature, evenwhen the SmaRTClock is running. If the current meter is measuring a current higher than 1 uA, then the deviceis not configured properly; one or more GPIO pins are sourcing current to an external circuit, or a high-speedsignal is being applied to a port pin (e.g., an external CMOS clock).

Software Considerations—The proper entry and exit procedures should be used when entering and exiting alow-power mode. This ensures that the device will work in a reliable and predictable manner.

SmaRTClock Alarm Events—The SmaRTClock ALRM flag is not persistent and is automatically cleared byhardware after 1 SmaRTClock cycle. The RTCAWK flag in the PMU0CF register is persistent and can be usedto detect a SmaRTClock alarm event after the ALRM flag has been cleared.

Flash Memory Operations—If erasing Flash memory, be sure to set the SmaRTClock alarm interval to a valuelonger than 36 ms to ensure that an alarm is not missed. When writing Flash memory, ensure that the alarminterval is longer than 71 µs.

Measuring Current—The software supplied with this application note allows the digital supply currentspecification in the data sheet to be achieved. Any current flowing through the GPIO pins is in addition to thedigital supply current required to operate the device. For example, driving a 24.5 MHz clock signal on a GPIOpin with a 3.3 V supply voltage can increase the supply current by 3 mA.

3. Power Modes Overview

The C8051F9xx family of MCUs support five power modes: Normal, Idle, Stop, Suspend and Sleep. A summary ofthe power modes can be found in Table 1. Detailed descriptions of each mode can be found in the PowerManagement chapter of the device data sheet.Normal and Idle modes are classified as Active Power Modes because the system clock is active and powerconsumption scales with the clock frequency. Typical supply currents for each of the three different system clocksources (24.5 MHz Precision Oscillator, 20 MHz Low Power Oscillator, and 32.768 kHz SmaRTClock Oscillator)are provided in Table 1. Stop, Suspend, and Sleep modes are classified as Inactive Power Modes because thesystem clock is stopped.

Since the system clock in most low-power applications is not always present, the C8051F9xx MCUs have an ultralow-powerSmaRTClock that can be used for timekeeping. The SmaRTClock oscillator requires less than 1 uA ofsupply current and can remain functional even when the MCU goes into its lowest power Sleep mode.

4. Minimizing Active Mode Current

The active modes in a low-power system typically require the most supply current; however, they are the modes inwhich the most critical system tasks are completed. Minimizing Active mode time is one of the best power savingstrategies. This can be achieved by operating at the fastest possible system clock frequency. Since the MCU ismost efficient at fast system clocks, minimizing active mode time results in greater overall benefit than reducingpeak current.

The following figures show the typical supply current in Normal and Idle modes as a function of the system clockfrequency. There are two observations to note about the Normal mode curves: 1) at the crossover point, the slopeof the supply current vs. frequency curve changes. This divides the curve into two piece wise linear regions. 2) Theabsolute current per MHz decreases as the system clock frequency increases. At low frequencies, the CPUoperates at a higher µA/MHz. As frequency increases, the µA/MHz drops and can be less than 150 µA/MHz onsome devices.The Active supply current can be influenced by a number of factors including supply voltage, temperature, systemclock frequency, power mode, and other factors under the control of application software.

4.1. Effect of Supply Voltage

In most CMOS circuits, supply voltage has the greatest effect on supply current. However, since the C8051F9xxMCUs have an on-chip LDO for regulating the voltage supplied to the digital circuitry, supply voltage has a minimaleffect on supply current. In fact, the supply current variation over the entire input voltage range (1.8–3.6 V) istypically less than ±10 µA from the midpoint voltage of 2.7 V.

4.2. Effect of Temperature

Changes in temperature can affect the active supply current. As temperatures rise, the supply current alsoincreases, and as temperatures drop, the supply current decreases. The supply current variation over the entireoperating temperature range (–40 to +85 °C) is typically less than ±5% from the supply current measured at 25 °C.

4.3. Effect of System Clock Frequency

The system clock frequency has the most significant effect on the active supply current. As the clock frequencyincreases, supply current and power efficiency increase, as shown in the following figures. When executing a taskthat requires a fixed number of instructions, the system clock should be set as fast as possible. The limiting factorin increasing the system clock should be the ability of the power supply to handle the increased peak currents.For tasks that require a fixed amount of time to complete (e.g., waiting for a UART byte to be clocked in),

increasing the system clock actually decreases power efficiency because the peak current increases while noadditional work is being completed. In these situations, the system clock frequency should be minimized and the

CPU placed in Idle mode.

4.4. Effect of Power Mode

The C8051F9xx MCUs have two Active Power Modes in which the system clock is running. Normal mode powerconsumption is shown in Figure 1, Figure 3, and Figure 5, and Idle mode power consumption is shown in Figure 4,Figure 6, and Figure 6. As a rule of thumb, placing the CPU in Idle mode will typically reduce the supply current byapproximately 50%.

4.5. Optimizing Application Software

To achieve the supply current measurements listed in this application note and in the device data sheet, applicationsoftware must properly configure the device into its optimum power setting. These low-power optimizations forActive Power Modes are as follows:

1. For system clock frequencies greater than the crossover frequency, disable (bypass) the one-shot circuit bysetting the BYPASS bit (FLSCL.6) to logic 1. For system clock frequencies less than the crossover frequency,enable the one-shot circuit by clearing the BYPASS bit (FLSCL.6) to logic 0 and immediately following thisoperation with a write of a non-zero value to the FLWR register (only required for C8051F93x/2x devices). Adetailed description of the one-shot circuit can be found in the Flash chapter of the device data sheet. Leavingthe one-shot enabled for frequencies higher than the crossover frequency can result in 40% higher supplycurrent. Leaving the one-shot bypassed for frequencies less than crossover frequency can result in greater than500% increase in supply current.Note: The optimum one-shot crossover frequency is 14 MHz on C8051F91x/0x/9x/8x devices and 10 MHz on

2. If the Low Power Oscillator is not selected as the system clock source, clear all wake-up source flags by writing0x20 to the PMU0CF register. Always use direct writes or reads when accessing this register. Clearing thewake-up source flags allows the Low Power Oscillator to be automatically disabled by hardware when it is notneeded. This optimization reduces the supply current by 100 uA.

3. If the Precision Oscillator is not selected as the system clock source, disable the Precision Oscillator Bias byclearing the OSCBIAS bit (REG0CN.4) to logic 0. This optimization reduces the supply current by 85 uA.

4. When using one of the internal oscillators as the system clock source, disable the missing clock detector resetsource in the RSTSRC register. Always use direct writes or reads when accessing this register and be carefulnot to disable the VDD Monitor as a reset source. This optimization reduces the supply current by 10 uA.

5. Disable the 1.8 V supply monitor in systems that use an external supply monitor or when a proper supplyvoltage is guaranteed (e.g., a system that uses a permanent battery where behavior at battery end-of-life is adon’t care). This optimization reduces the supply current by 5 to 20 uA depending on supply voltage.

6. Whenever possible, try to execute code at the fastest possible clock frequency and use Idle mode to pausecode execution when waiting for a specific event to occur (e.g., timer overflow flag in a software delay loop,GPIO pin changing state, UART transmission or ADC conversion to complete, etc.).

7. If software contains small loops, such as a while(1) statement, ensure that the loop does not straddle a flashrow boundary. Devices with 1024 byte Flash pages have a row boundary of 128 bytes, and devices with 512byte Flash pages have a row boundary of 64 bytes. Supply current can increase by up to 30% when a shortloop straddles a Flash row boundary. See the Flash chapter of the MCU data sheet for more details aboutminimizing Flash read current.

C8051F9XX产品系列:

C8051F930, C8051F931, C8051F920, C8051F921, C8051F912, C8051F911, C8051F902, C8051F901,C8051F990, C8051F991, C8051F996, C8051F997, C8051F980, C8051F981, C8051F982, C8051F983,C8051F985, C8051F986, C8051F987, C8051F988, C8051F989

红外线测温仪

红外测温技术在生产过程中,在产品质量控制和监测,设备在线故障诊断和安全保护以及节约能源等方面发挥了着重要作用。近20年来,非接触红外人体测温仪在技术上得到迅速发展,性能不断完善,功能不断增强,品种不断增多,适用范围也不断扩大。比起接触式测温方法,红外测温有着响应时间快、非接触、使用安全及使用寿命长等优点。非接触红外测温仪包括便携式、在线式和扫描式三大系列,并备有各种选件和计算机软件,每一系列中又有各种型号及规格。在不同规格的各种型号测温仪中,正确选择红外测温仪型号对使用者来说是十分重要的。

应用

超小型温度校正仪,最大限度地克服了由于超小型化而带来的技术困难,使用户可以携带到工业现场的每一角落,对其需要检查、维修和标定的温度探头实施现场校验作业,免除将其拆卸取回实验室进行对比标定,又要重新装回原系统的麻烦,可以大大提高工作效率,节约时间,提高设备和系统的可用率,并且为现场自动控制工程师提供了优异的维修、校验手段。

AIKOM系列超小型温度校正仪,一改传统的温度校验模式,其应用领域之广泛,遍及工业领域温度测量和标定的每一环节,并提供了一个可调的模拟温度源,对提高工艺流程控制水平、产品质量保证以及防止工业过程自动保护定值的误动和寻找故障提供了重要的检查手段。特别是对于温度开关的定值检查,可以做到快速准确而方便,其应用领域涉及:

电力:燃煤发电厂、燃气供热电厂、水电站、核电站、地区供热管网、大型电力变压器的温度保护和信号传送等。

冶金:铝厂、铜厂、钢厂等。

石化:采油、输油管路、石化厂、炼油厂。

一般工业:冷冻机厂、空调厂、冰箱厂、啤酒厂、制药厂、汽车厂。

温度元件制造厂:铂电阻、热电偶及补偿导线电缆、温度开关、温度传感器制造厂。

交通运输:机场的飞机维修、大型运输动力系统维修、远洋海运作为在役维修测量手段。

Aikom产品在中国市场推出的主要有二个系列(PD-1000/PD-2000)四种型号。PD-1025特点是采用半导体制冷技术,在摄氏20度环境温度下最低温度可以达到-25度,高温能达到 105度。PD-2300的特点是槽体有效尺寸深,加热元件使用24V直流,安全性好和静电影响小,利用机内风扇冷却而不需要外压缩空气,采用锥形槽体和传热套管,热阻极小传热快,温场经过特殊补偿,温度范围为环境温度至摄氏400度。

PD-2800的特点是可以提供摄氏720度的高温源,升降温速度快,使用方便,操作简单,经济实用,特别适用于工业现场使用。但由于采肒型热电偶作为槽体测温元件,适用于高温而精度要求不高场稀?BR>PD-2600是Aikom公司最新推出的高精度,高稳定性,高温槽体,标定后的精度为正负0.3℃满量程非线性误差。它还可以通过选购一个软件,用以实现十段可编程升降温速率控制,用来模拟和实现工业现场实际工艺流程。也可以输入1-5V过程电压信号,用以改变槽体控温单元的设定值构成环路控制。总之,它是一台功能强大的计算机程控小型便携式恒温槽,是世界上同类产品中性能优异的代表作。

采用红外成像检测技术可以对正在运行的设备进行非接触检测,拍摄其温度场的分布、测量任何部位的温度值,据此对各种外部及内部故障进行诊断,具有实时、遥测、直观和定量测温等优点,用来检测发电厂、变电所和输电线路的运转设备和带电设备非常方便、有效。

利用热像仪检测在线电气设备的方法是红外温度记录法。红外温度记录法是工业上用来无损探测,检测设备性能和掌握其运行状态的一项新技术。与传统的测温方式(如热电偶、不同熔点的蜡片等放置在被测物表面或体内)相比,热像仪可在一定距离内实时、定量、在线检测发热点的温度,通过扫描,还可以绘出设备在运行中的温度梯度热像图,而且灵敏度高,不受电磁场干扰,便于现场使用。它可以在-20℃~2000℃的宽量程内以0.05℃的高分辨率检测电气设备的热致故障,揭示出如导线接头或线夹发热,以及电气设备中的局部过热点等等。

带电设备的红外诊断技术是一门新兴的学科。它是利用带电设备的致热效应,采用专用设备获取从设备表面发出的红外辐射信息,进而判断设备状况和缺陷性质的一门综合技术。

红外测温

1、红外测温仪器的种类

红外测温仪器主要有3种类型:红外热像仪、红外热电视、红外测温仪(点温仪)。60年代我国研制成功第一台红外测温仪,八十年代初期以后又陆续生产小目标、远距离、适合电业生产特点的测温仪器,如西光IRT-1200D型、HCW-Ⅲ型、HCW-Ⅴ型;YHCW-9400型;WHD4015型(双瞄准,目标D 40mm,可达15 m)、WFHX330型(光学瞄准,目标D 50 mm,可达30 m)。美国生产的PM-20、30、40、50、HAS-201测温仪;瑞典AGA公司TPT20、30、40、50等也有较广泛的应用。DL-500 E可以应用于110~500 kV变电设备上,图像清晰,温度准确。红外热像仪,主要有日本TVS-2000、TVS-100,美国PM-250,瑞典AGA- THV510、550、570。国产红外热像仪在昆明研制成功,实现了国产化。

2、红外测温仪工作原理

了解红外测温仪的工作原理、技术指标、环境工作条件及操作和维修等是用户正确地选择和使用红外测温仪的基础。光学系统汇集其视场内的目标红外辐射能量,视场的大小由测温仪的光学零件以及位置决定。红外能量聚焦在光电探测仪上并转变为相应的电信号。该信号经过放大器和信号处理电路按照仪器内部的算法和目标发射率校正后转变为被测目标的温度值。除此之外,还应考虑目标和测温仪所在的环境条件,如温度、气氛、污染和干扰等因素对性能指标的影响及修正方法。

一切温度高于绝对零度的物体都在不停地向周围空间发出红外辐射能量。物体的红外辐射能量的大小及其按波长的分布——与它的表面温度有着十分密切的关系。因此,通过对物体自身辐射的红外能量的测量,便能准确地测定它的表面温度,这就是红外辐射测温所依据的客观基础。

黑体辐射定律:黑体是一种理想化的辐射体,它吸收所有波长的辐射能量,没有能量的反射和透过,其表面的发射率为1。应该指出,自然界中并不存在真正的黑体,但是为了弄清和获得红外辐射分布规律,在理论研究中必须选择合适的模型,这就是普朗克提出的体腔辐射的量子化振子模型,从而导出了普朗克黑体辐射的定律,即以波长表示的黑体光谱辐射度,这是一切红外辐射理论的出发点,故称黑体辐射定律。

物体发射率对辐射测温的影响:自然界中存在的实际物体,几乎都不是黑体。所有实际物体的辐射量除依赖于辐射波长及物体的温度之外,还与构成物体的材料种类、制备方法、热过程以及表面状态和环境条件等因素有关。因此,为使黑体辐射定律适用于所有实际物体,必须引入一个与材料性质及表面状态有关的比例系数,即发射率。该系数表示实际物体的热辐射与黑体辐射的接近程度,其值在零和小于1的数值之间。根据辐射定律,只要知道了材料的发射率,就知道了任何物体的红外辐射特性。

影响发射率的主要因纱在:材料种类、表面粗糙度、理化结构和材料厚度等。

当用红外辐射测温仪测量目标的温度时首先要测量出目标在其波段范围内的红外辐射量,然后由测温仪计算出被测目标的温度。单色测温仪与波段内的辐射量成比例;双色测温仪与两个波段的辐射量之比成比例。

红外系统:红外测温仪由光学系统、光电探测器、信号放大器及信号处理、显示输出等部分组成。光学系统汇聚其视场内的目标红外辐射能量,视场的大小由测温仪的光学零件及其位置确定。红外能量聚焦在光电探测器上并转变为相应的电信号。该信号经过放大器和信号处理电路,并按照仪器内疗的算法和目标发射率校正后转变为被测目标的温度值。

热像仪

红外热像仪是利用红外探测器、光学成像物镜和光机扫描系统(先进的焦平面技术则省去了光机扫描系统)接受被测目标的红外辐射能量分布图形反映到红外探测器的光敏元上,在光学系统和红外探测器之间,有一个光机扫描机构(焦平面热像仪无此机构)对被测物体的红外热像进行扫描,并聚焦在单元或分光探测器上,由探测器将红外辐射能转换成电信号,经放大处理、转换或标准视频信号通过电视屏或监测器显示红外热像图。这种热像图与物体表面的热分布场相对应;实质上是被测目标物体各部分红外辐射的热像分布图由于信号非常弱,与可见光图像相比,缺少层次和立体感,因此,在实际动作过程中为更有效地判断被测目标的红外热分布场,常采用一些辅助措施来增加仪器的实用功能,如图像亮度、对比度的控制,实标校正,伪色彩描绘等技术

责任编辑:Davia

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)