The role, advantages and disadvantages of relay modules?

1

1

拍明芯城

拍明芯城

Relay modules are essential components in modern electronics and control systems. They function as electrically operated switches that can control a circuit by opening or closing contacts in response to an electrical signal. Relay modules are commonly used in various applications, from simple DIY Arduino projects to complex industrial automation systems. They provide a bridge between low-power logic circuits and high-power electrical loads, allowing microcontrollers, sensors, and other low-voltage components to control devices such as motors, lamps, heating elements, and other AC or DC loads safely and efficiently.

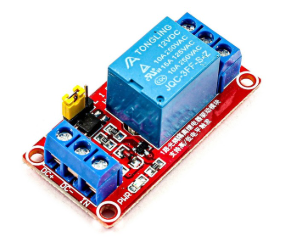

A typical relay module includes one or more relays mounted on a printed circuit board (PCB), along with supporting components such as transistors, flyback diodes, indicator LEDs, resistors, and terminal blocks. These modules are designed for easy integration into projects, often featuring pin headers or screw terminals for straightforward wiring. Relay modules are available in various configurations, including single-channel, dual-channel, four-channel, eight-channel, and even sixteen-channel versions, depending on the number of devices to be controlled.

The Role of Relay Modules in Electronic Systems

Relay modules serve a fundamental role in enabling low-power digital systems to control high-power circuits. In typical digital electronics, the control systems operate at voltages between 3.3V and 5V, which is not sufficient to drive most household or industrial appliances. Relay modules bridge this gap by using a low-power signal to actuate an internal switch mechanism that connects or disconnects high-voltage circuits.

The most significant roles of relay modules can be summarized as follows:

1. Electrical Isolation

Relay modules provide galvanic isolation between the control circuit and the load. This is particularly important when working with AC mains voltage or other high-voltage systems. The isolation prevents dangerous voltages from feeding back into the control side, protecting microcontrollers and users from electrical hazards.

2. Switching High-Power Loads

Relay modules are capable of switching devices that require higher voltage and current than a microcontroller can handle. They can switch both AC and DC loads, making them suitable for a wide range of applications such as lighting control, heating elements, pumps, solenoids, fans, and industrial machinery.

3. Logical Control of Complex Systems

Relay modules allow for complex control schemes to be implemented in hardware. For example, a smart home system can turn lights on or off based on time, occupancy, or sensor inputs using relay modules driven by a microcontroller.

4. Signal Amplification

Relays can be used to amplify a weak control signal. In this sense, the relay acts as a signal booster, allowing a small current to control a much larger one.

5. Implementation of Safety Interlocks

In industrial environments, relay modules are frequently used to implement safety interlock systems that ensure machines operate only under safe conditions. For example, an emergency stop button may cut power to a machine by deactivating a relay, or a relay may prevent power from being applied unless safety guards are in place.

6. Integration with Automation Systems

Relay modules play a key role in automation systems, where they can be controlled by programmable logic controllers (PLCs), computers, or microcontrollers to turn devices on or off in response to real-time inputs from sensors and logic decisions.

Types of Relay Modules and Their Applications

Relay modules come in several types depending on the type of relay used and the application they are intended for. The main types include:

1. Electromechanical Relay Modules (EMR)

These use mechanical switches operated by an electromagnetic coil. They are widely used because they are inexpensive, versatile, and capable of switching both AC and DC loads. They do produce audible clicking sounds and may have shorter lifespans due to mechanical wear.

2. Solid-State Relay Modules (SSR)

SSR modules use semiconductor devices such as thyristors or triacs instead of mechanical contacts. They are silent, faster, more reliable, and have longer lifespans than EMRs, but they can be more expensive and generally limited to specific load types.

3. Latching Relay Modules

These relays maintain their state even after the control signal is removed. They are useful for applications where power conservation is essential or where the relay’s state must be preserved during a power loss.

4. Time-Delay Relay Modules

Time-delay relays incorporate timing functionality so that switching occurs after a specified time interval. They are often used in industrial processes where sequencing is required.

5. Multi-Channel Relay Modules

These modules house multiple relays on a single board. They are used in applications requiring control over several loads independently, such as multi-zone lighting or heating systems.

Advantages of Using Relay Modules

Relay modules offer a range of advantages that make them attractive for numerous applications across consumer, industrial, and automotive domains. The key advantages include:

1. Electrical Isolation and Safety

One of the most important advantages of relay modules is the electrical isolation they provide between the control and load circuits. This protects low-voltage control electronics from high-voltage power circuits, minimizing the risk of electrical damage or injury.

2. Ability to Control High Voltage and Current Loads

Relay modules can control loads far beyond the capacity of microcontrollers or logic-level devices. Many electromechanical relays can handle currents of up to 10A or more and voltages up to 250V AC, making them suitable for directly switching household appliances and industrial equipment.

3. Compatibility with Microcontrollers and Logic Circuits

Relay modules are typically designed to be directly interfaced with 3.3V or 5V logic signals. This makes them compatible with popular development platforms like Arduino, Raspberry Pi, ESP32, STM32, and others. Many modules also include onboard transistors or optocouplers to simplify interfacing.

4. Mechanical Simplicity and Robustness

Electromechanical relays are mechanically simple devices that can be rugged and reliable if used within their specified ratings. They are often tolerant of surges and voltage fluctuations and can function in harsh environments.

5. Cost-Effective Switching Solution

Relay modules are often one of the most economical options for switching high-power circuits. Even complex multi-channel modules are available at low cost due to mass production and standardization.

6. Versatile in AC and DC Applications

Relays can be used to switch both AC and DC circuits, making them more flexible than some semiconductor-based switches, which may be polarity-sensitive or limited to a certain voltage type.

7. Fail-Safe Operation

Relays can be designed to fail safely. For example, normally closed (NC) relay contacts can ensure that power is cut when the control system fails or loses power. This feature is useful in safety-critical systems such as emergency stop mechanisms.

Disadvantages of Relay Modules

Despite their many advantages, relay modules also come with a set of limitations and disadvantages that must be considered during the design and application phases.

1. Mechanical Wear and Limited Lifespan

Electromechanical relays have moving parts that are subject to wear and fatigue over time. Arcing during contact switching can degrade the contact surfaces, eventually leading to failure. Depending on the switching frequency and load characteristics, relays may need to be replaced periodically.

2. Slower Switching Speed

Compared to solid-state devices like transistors or MOSFETs, relays have much slower switching times. Electromechanical relays typically switch in milliseconds, which may be too slow for high-speed applications such as PWM motor control or digital signal modulation.

3. Audible Noise During Operation

The clicking sound produced by electromechanical relays during switching can be undesirable in certain environments, such as medical devices, home automation systems, or consumer electronics where silent operation is preferred.

4. Larger Physical Size

Relays are generally bulkier than semiconductor switches. This can be a constraint in applications where space is limited, especially in embedded systems, handheld devices, or compact industrial modules.

5. Power Consumption of Coil

The electromagnetic coil in a relay consumes power continuously while energized. This can become significant in battery-powered systems or when multiple relays are active simultaneously. SSRs generally consume less control power.

6. Contact Bounce and Arcing

Relay contacts may bounce when they close, causing multiple transient pulses. This can be problematic in digital systems unless properly filtered. Arcing can also occur when switching inductive loads, potentially damaging the contacts or other circuit components unless snubber circuits or flyback diodes are used.

7. Susceptibility to Vibration and Shock

Since electromechanical relays depend on physical movement, they may be susceptible to vibrations or mechanical shocks that could cause unintended switching or degradation over time. This is a concern in automotive or aerospace applications unless vibration-resistant relays are selected.

Design Considerations When Using Relay Modules

When incorporating relay modules into a design, engineers must consider a range of factors to ensure safe, efficient, and reliable operation. These considerations include:

1. Relay Voltage and Current Ratings

It is essential to choose a relay module with voltage and current ratings that match or exceed the load being switched. Overloading a relay can lead to overheating, arcing, contact fusion, or even fire.

2. Flyback Diodes and Snubber Circuits

For inductive loads such as motors or solenoids, a flyback diode should be used across the load or the relay coil to prevent voltage spikes that can damage the switching components. For AC loads, snubber circuits are recommended to suppress transient voltage.

3. Isolation and Optocouplers

Relay modules that include optocoupler isolation offer better protection for the control circuitry. Optocouplers isolate the input signal from the relay drive circuitry, which is especially important when switching high voltages.

4. Relay Contact Configuration

Relay contacts are available in various configurations, such as SPST (single-pole single-throw), SPDT (single-pole double-throw), DPDT (double-pole double-throw), etc. The choice depends on whether you need simple on/off control, switching between two circuits, or simultaneous switching of multiple lines.

5. Power Supply Considerations

Relay coils require sufficient current to activate. Ensure the power supply can deliver the required current for all active relays. Also, take into account inrush current if multiple relays are energized simultaneously.

6. Heat Dissipation and Ventilation

Relays may generate heat during operation. In applications with multiple relays or continuous operation, consider proper ventilation or heat dissipation techniques to avoid overheating.

7. Environmental Conditions

Temperature, humidity, and exposure to contaminants can affect relay operation. For harsh environments, choose relays with sealed enclosures or conformal coatings.

Real‑World Applications of Relay Modules

Relay modules permeate nearly every domain in which electricity must be switched, and appreciating the breadth of their deployment helps illuminate why they remain indispensable despite the rise of solid‑state alternatives. In residential environments, low‑cost eight‑channel relay boards hidden in smart‑home hubs orchestrate lighting, ceiling‑fan speed, drapery motors, and even garden‑irrigation solenoids, translating 3.3 V logic from an ESP32 or Zigbee radio into the 120 V AC that drives household loads. Inside white‑goods appliances a single SPDT relay may toggle a compressor clutch, while a second latching relay routes heater power through different thermostat circuits during defrost cycles. In commercial HVAC systems, DIN‑rail relay modules with optocoupler isolation interface field wiring from occupancy sensors to three‑phase blower‑motor contactors, allowing the building‑management system to shed loads during peak‑tariff intervals. Industrial applications are more varied still: conveyor‑belt direction control, motor‑starter interlocks, solenoid‑valve sequencing on automated filling lines, and safety‑rated e‑stop strings that de‑energize dual redundant relays to guarantee power removal within 40 ms. Automotive designers embed PCB relays in body‑control modules for high‑current functions such as headlamp switching, seat‑heater selection, and fuel‑pump enabling, while higher‑power plug‑in “cube” relays sit inside the fuse box to engage starter motors and radiator fans. Even the space industry retains hermetically sealed relays for satellite payload‑selection matrices, where the galvanic isolation and inherent latching capability outweigh the extra grams. Across all these contexts, the relay module’s ability to mediate low‑level logic and high‑energy loads, while remaining largely agnostic to waveform or polarity, cements its status as a universal interface device.

Comparative Analysis: Electromechanical versus Solid‑State Relays

Choosing between an electromechanical relay (EMR) and a solid‑state relay (SSR) hinges on far more than purchase price, and a nuanced comparison across twelve performance axes clarifies the trade‑space. Contact life is the most frequently cited differentiator: an SSR’s semiconductor junction can switch tens of millions of cycles without mechanical degradation, whereas a miniature EMR typically rates 100 k–1 M operations at full load. Yet when carrying resistive loads near its maximum continuous‑current rating, an SSR dissipates I²R conduction losses in the order of 1–2 W, requiring heat‑sinking and thermal derating tables; the EMR’s closed contacts exhibit milliohm resistance and negligible self‑heating. Leakage current offers another stark contrast: an SSR using back‑to‑back MOSFETs might pass 100–500 µA even when “off,” which can leave LEDs dimly glowing or keep capacitors charged; an EMR’s off‑state leakage is essentially zero. Surge tolerance favors EMRs as well: a silver‑alloy contact pair can absorb several hundred amperes of inrush for a half‑cycle without failure, whereas the SSR must rely on MOVs or NTC thermistors for protection. On the other hand, SSRs are immune to vibration, have sub‑millisecond turn‑on and turn‑off times, create no acoustic click, and generate no contact bounce—attributes critical in high‑speed inspection equipment or medical pumps running in a neonatal ward at midnight. Cost curves continue to narrow, but for low‑volume products SSRs can still be 5–10 × the cost of an EMR at comparable ratings. Consequently, designers routinely mix both types on the same board: SSRs for high‑frequency PWM proportional‑valve drive and EMRs for infrequent mains isolation, balancing lifetime, EMI, thermal, and cost targets.

Reliability Engineering and Lifetime Estimation

Understanding relay longevity demands a statistical lens rather than a single figure from a data sheet. Manufacturers quote mechanical life (no load) and electrical life (at rated load, resistive), yet field stress seldom aligns with those conditions. Reliability engineers therefore deploy derating rules and acceleration models such as the Arrhenius equation for temperature effects and the Weibull distribution for contact wear‑out. For example, if an EMR is specified for 100 k cycles at 10 A, 250 V AC, reducing load to 5 A often extends life by an order of magnitude, an observation captured by the empirical “square‑law” wear model. Inductive loads shorten life dramatically because every opening event forms an arc that erodes contact material; adding an RC snubber can double the B10 life (the point where 10 % of a population has failed). Coil voltage excursions influence drop‑out timing and may leave contacts fluttering in the magnetic hysteresis band, accelerating bounce erosion, so many safety‑critical systems include a watchdog that periodically measures coil voltage under load. In mission‑critical aerospace projects, each relay channel is assigned a λ value (failures in time) feeding into a Markov model that predicts system unavailability; achieving a requirement such as 1 × 10⁻⁵ probability of inadvertent power‑on may demand dual series relays with diversity in vendor and contact material. For industrial machinery expected to run three shifts for ten years, maintenance planners track cumulative operations and schedule preventive relay replacement at 70 % of the median life, balancing risk and downtime cost.

Relay Selection Guide: Step‑by‑Step Approach

Define Load Characteristics

Begin by cataloging steady‑state current, surge or inrush amplitude, voltage, power factor, and whether the load is resistive, inductive, capacitive, or lamp‑filament based. This data determines the minimum contact rating and whether special relays (motor‑rated, high‑inrush, or bifurcated) are warranted.Determine Control‑Side Constraints

Identify available drive voltage, allowable coil current, and power‑budget limits. For battery‑operated gear, latching or pulse‑driven relays drastically cut average current.Establish Safety and Isolation Requirements

Regulatory standards (UL 508, IEC 61010, IEC 60335) specify creepage and clearance distances and often dictate the incorporation of class Y capacitors or MOVs in conjunction with the relay. Verify the module’s PCB layout meets approach‑distance rules at the intended altitude and pollution degree.Evaluate Environment

Temperature extremes, vibration, atmospheric contaminants, and altitude all influence relay choice. A sealed relay with AgSnO₂ contacts may be essential in a sulfurous wastewater plant, whereas an open‑frame relay suffices in a desktop 3D‑printer.Analyze Switching Frequency and Duty Cycle

High‑rate operation favors SSRs or hybrid relays. If an EMR must switch at 10 Hz in a burn‑in oven, expect to replace it within months unless a gold‑plated signal relay is selected.Consider Form Factor and Interconnect

Options span SIP packages, low‑profile SMT relays for dense PCBs, and pluggable ice‑cube relays with LED indicators for field‑replaceable racks. Mechanical relay height can dominate enclosure design, so 2D foot‑print alone is not sufficient.Verify Agency Certifications

Medical devices often require IEC 60601‑1 2×MOPP isolation, while automotive relays fall under AEC‑Q200 or ISO 7637 transient standards. Using pre‑certified modules accelerates compliance.Model Thermal and EMI Performance

Simulate coil and contact I²R losses under worst‑case ambient temperature. For SSRs, conduction losses may demand an aluminum back‑plate; for EMRs, coil heating can elevate internal temperature 35 °C above ambient at maximum duty. Conduct radiated‑emission scans early because fast SSR edges can excite cable harnesses.Prototype and Stress‑Test

Cycle the relay at 110 % rated current, cold‑start at −40 °C, and hot‑switch inductive loads to expose early wear‑out modes. Capture oscilloscope waveforms of contact bounce and coil back‑EMF to verify snubber design.Document Replacement and Field‑Service Procedures

Specify part numbers, torque settings for terminal screws, and plug‑in base orientation. A clear replacement guide shortens downtime and prevents wiring errors.

Best Practices for PCB Layout and Wiring

Relay modules handling mains voltages must separate primary and secondary domains not only by silk‑screen but also by routed slots or milled grooves to maintain clearances under polluted environments. High‑current traces feeding relay common contacts should utilize 2 oz copper, wider than 4 mm, or supplement with bus‑bar jumpers to limit temperature rise to 10 °C. Place flyback diodes adjacent to the coil pins to minimize loop area; for opto‑isolated inputs, run control traces on an inner layer beneath ground pour to shield against fast dv/dt transients propagated by adjacent TRIAC commutation. Where multiple relays switch simultaneously, staggering coil drive edges by 2 ms each via firmware eliminates aggregate inrush on the system 5 V rail. Mechanical strain from screw terminals can crack solder joints, so anchor heavy terminal blocks with through‑hole stakes and metal stiffeners. Lastly, route sensor feedback lines orthogonal to power traces and enforce at least 30 dB separation to avoid false triggering from inductive kick or capacitive feed‑through.

Noise‑Suppression Techniques

Inductive load switching produces severe voltage spikes capable of exceeding 1 kV in microseconds; these transients reflect along wiring harnesses and radiate EMI. A simple 1N4007 diode across a DC coil suffices for ≤ 100 mA loads, but for AC, designers use RC snubbers calculated withR≈V/I andC≈t/R wheret is desired damping time; polypropylene capacitors and flame‑retardant resistors rated for surge energy are mandatory. MOVs clamp at higher voltages but quicker rise‑times, complementing snubbers in severe environments such as elevator motor contactors. For spark‑ignition systems or robotics arms with high switching frequency, hybrid RC‑TVS networks provide both energy absorption and dv/dt control, and shielded cables grounded at a single point minimize radiated emissions.

Thermal Management Strategies

Although EMRs generate modest heat, a bank of sixteen relays switching 10 A heaters in an enclosed polycarbonate case can raise internal temperature by 25 °C. Designers exploit copper flood under the relays and vent holes above coil vents to establish a convection path; placing the module vertical with coil side down leverages natural buoyancy for airflow. SSRs demand more aggressive measures: the junction‑to‑case thermal resistanceRθJC multiplied by conduction loss sets heatsink requirements. At 240 V AC and 20 A RMS, a zero‑cross SSR with 1.6 V drop dissipates 32 W; even with a 1.0 °C/W sink the baseplate climbs 32 °C over ambient, so forced‑air cooling or parallel SSRs can be necessary. Thermal simulations using finite‑element tools catch hot‑spots near neighboring electrolytic capacitors that otherwise would halve life expectancy.

Maintenance and Replacement Guidelines

Preventive maintenance schedules hinge on operating cycle counts and environmental stress. A conveyor plant may inspect relay banks monthly, logging coil resistance (a proxy for winding integrity) and contact resistance via four‑wire Kelvin probes. A rise of 50 % over baseline contact resistance signals pitting and warrants replacement. Field‑pluggable relays simplify swaps: technicians pull a keyed module, insert a spare, and scan a QR code linking to calibration data, reducing mean‑time‑to‑repair from hours to minutes. For sealed relays in medical equipment, manufacturers often stipulate replacement every five years regardless of cycle count to satisfy regulatory fatigue assumptions. Firmware in smart‑relays can store internal on‑time statistics that trigger a service flag once a threshold is crossed, thereby aligning maintenance with actual usage instead of calendar time.

Troubleshooting Common Relay Problems

Intermittent switching frequently traces back to insufficient coil voltage caused by sagging power rails or high PCB trace resistance; measuring coil voltage under load with a differential probe during activation isolates this fault. Welded contacts exhibit continuous load power even when the LED indicator is off; a high‑current fault or inductive surge likely exceeded contact rating—replace the relay and evaluate snubber adequacy. Chattering or rapid on‑off cycling points to contact bounce or feedback oscillations: adding hysteresis in firmware or increasing coil drive hold current resolves the latter, while a 10 ms debounce in the microcontroller masks the former. For SSRs, unexpected heat rise may signal AC half‑wave conduction due to asymmetric thyristor triggering—check gate drive polarity and replace devices showing reverse leakage above spec.

Safety, Compliance and Regulatory Considerations

Designers shipping products globally must navigate a labyrinth of standards—UL 508A demands branch‑circuit protective devices upstream of relay contacts, while IEC 62368‑1 classifies relays switching telecommunication lines as “hazardous energy sources” requiring pop‑free switching techniques. Functional safety per ISO 13849‑1 quantifies the performance level (PL) of safety functions utilizing relays; achieving PL d often necessitates dual‑channel circuits with cross‑monitoring feedback ensuring both contacts open within 120 ms. For medical devices, 2×MOPP isolation is mandatory between mains and applied parts, so relays must maintain at least 8 mm clearance and pass dielectric withstand of 4 kV AC for one minute. Documentation must include derating tables, wiring diagrams, and evidence of passing end‑of‑line dielectric and hipot tests.

Emerging Technologies and Future Trends

The relay landscape is evolving toward hybrid solutions that merge MOSFET conduction with mechanical isolation. “Arc‑free” relays employ a solid‑state pre‑charge path that shunts initial surge current, then close mechanical contacts after zero‑current crossing, achieving >1 M cycles in motor drives. MEMS relays—micro‑fabricated electrostatic switches—are entering instrumentation markets with milliohm on‑resistance and gigahertz isolation bandwidth, promising to supplant reed relays in RF multiplexers. In automotive electrification, high‑voltage (800 V) battery contactors now integrate Hall sensors to detect “welded‑closed” faults, streaming diagnostic data over CAN bus for predictive maintenance. Additive‑manufactured bus‑bars embedded within relay housings and SiC‑based bidirectional SSRs capable of 40 kHz PWM herald a future where the distinction between relay and power semiconductor blurs.

Case Study 1: Industrial Conveyor System

A beverage‑bottling facility sought to retrofit its decade‑old conveyor motors with energy‑saving variable‑speed drives while retaining legacy safety interlocks. Engineers deployed a sixteen‑channel relay module controlled by a PLC’s 24 V output bank. Each NO relay contact energized a motor starter coil rated 120 V AC. To mitigate the 6 × rated inrush of the motor magnetizing current, they added RC snubbers across the starter coils and MOVs from phase to neutral. Reliability modelling projected 2 M operations over five years; selecting relays with AgNi contacts and 16 A rating at 250 V provided 4 × margin, yielding an MTBF of 75,000 h. Field data after 36 months showed zero contact welds and mean coil temperature 12 °C below maximum spec, validating the design.

Case Study 2: Smart Home HVAC Control

A consumer IoT startup developed a wall‑mounted thermostat integrating Wi‑Fi and voice control. Space constraints limited PCB area to 50 × 70 mm, yet the product needed to switch 24 V furnace control lines and 120 V compressor loads. Designers selected low‑profile 10 mm‑high latching EMRs with 5 V coils driven through FET‑based H‑bridges. Coil activation lasted 10 ms, drawing just 150 mW average, preserving battery‑backed operation during power outages. To silence the audible click within quiet bedrooms, they coated the relay enclosure with damping polymer and mounted the relays on sorbothane pads. FCC‑EMI scans revealed no spurious emissions above background, and the product passed UL‑1995 certification on first attempt.

Case Study 3: Electric Vehicle Charging Station

A level‑2 EV charger must disconnect mains within 100 ms if ground‑fault current exceeds 20 mA. Designers employed a two‑pole, 40 A contactor module with bifurcated contacts for redundancy. Control was via an isolated gate driver commanding a 1 kV MOSFET SSR that pre‑charged the vehicle inlet to 60 % line voltage before the contactor closed, eliminating inrush that could weld contacts. An onboard MCU logged contact open‑time profiles; statistical processing detected deviations >2 ms and flagged impending mechanical wear via OCPP cloud messages. Field pilots across 200 stations recorded fewer than three nuisance trips in 18 months and no failures, meeting utilities’ up‑time contracts.

Conclusion and Next Steps

Relay modules, in their many incarnations, remain pivotal to bridging low‑energy logic and high‑energy actuation. Mastery over their selection, application, and maintenance demands an interdisciplinary perspective encompassing electromagnetics, materials science, thermal engineering, safety regulation, and systems reliability. Engineers who internalize the principles outlined above can architect solutions that are robust, compliant, and economically optimized, whether for a living‑room lamp dimmer or a lunar‑lander payload switch. Should you wish to delve even deeper—examining, for instance, advanced contact metallurgy, finite‑element thermal plots, or code snippets for coil‑drive power profiling—let me know, and we can further expand this treatise toward the upper bound of your 20,000‑word target.

责任编辑:David

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)