TI LM3S818三相无刷直流(BLDC)马达驱动方案

74

74

拍明

拍明

原标题:TI LM3S818三相无刷直流(BLDC)马达驱动方案

TI公司的LM3S818工作频率高达50MHz的基于ARM® Cortex™-M3控制器核的32位MCU,具有32位RISC性能,集成了64kB闪存和8kB SRAM,并具有实时工业连接,SSI/SPI控制器,和2个UART. LM3S818具有6个运动控制PWM输出,用于位置监视的正交编码器以及低等待关断的故障保护输入.目标应用在工厂自动化和控制,建筑物和家庭自动化,步进马达, 无刷直流(BLDC)马达和交流感应电动机.本文介绍了LM3S818主要特性,方框图, Stellaris® LM3S818 controlCARD模块主要特性,框图,电路图和模块元件布局图.

The Stellaris® LM3S818 microcontroller is based on the ARM® Cortex™-M3 controller core operating at up to 50 MHz, with 64 kB flash and 8 kB SRAM. The LM3S818 also features real-time industrial connectivity, with an SSI / SPI controller, and 2 UARTs. The LM3S818 microcontroller also features advanced motion control features, including 6 motion-control PWM outputs with dead-band, a quadrature encoder input for precise position monitoring, and a fault protection input for low-latency shutdown. The microcontroller also features intelligent analog capability, including 1 analog comparators and 6 channels of highly accurate 10-bit analog-to-digital conversion - with the ability to sample at speeds of 1M samples per second.

LM3S818主要特性:

The LM3S818 microcontroller includes the following product features:

■ 32-Bit RISC Performance

– 32-bit ARM® Cortex™-M3 v7M architecture optimized for small-footprint embedded

Applications

– System timer (SysTick), providing a simple, 24-bit clear-on-write, decrementing, wrap-on-zero counter with a flexible control mechanism

– Thumb®-compatible Thumb-2-only instruction set processor core for high code density

– 50-MHz operation

– Hardware-division and single-cycle-multiplication

– Integrated Nested Vectored Interrupt Controller (NVIC) providing deterministic interrupt

handling

– 26 interrupts with eight priority levels

– Memory protection unit (MPU), providing a privileged mode for protected operating system functionality

– Unaligned data access, enabling data to be efficiently packed into memory

– Atomic bit manipulation (bit-banding), delivering maximum memory utilization and streamlined peripheral control

ARM® Cortex™-M3 Processor Core

– Compact core.

– Thumb-2 instruction set, delivering the high-performance expected of an ARM core in the memory size usually associated with 8- and 16-bit devices; typically in the range of a few kilobytes of memory for microcontroller class applications.

– Rapid application execution through Harvard architecture characterized by separate buses for instruction and data.

– Exceptional interrupt handling, by implementing the register manipulations required for handling an interrupt in hardware.

– Deterministic, fast interrupt processing: always 12 cycles, or just 6 cycles with tail-chaining

– Memory protection unit (MPU) to provide a privileged mode of operation for complex

applications.

– Migration from the ARM7™ processor family for better performance and power efficiency.

– Full-featured debug solution

• Serial Wire JTAG Debug Port (SWJ-DP)

• Flash Patch and Breakpoint (FPB) unit for implementing breakpoints

• Data Watchpoint and Trigger (DWT) unit for implementing watchpoints, trigger resources, and system profiling

• Instrumentation Trace Macrocell (ITM) for support of printf style debugging

• Trace Port Interface Unit (TPIU) for bridging to a Trace Port Analyzer

– Optimized for single-cycle flash usage

– Three sleep modes with clock gating for low power

– Single-cycle multiply instruction and hardware divide

– Atomic operations

– ARM Thumb2 mixed 16-/32-bit instruction set

– 1.25 DMIPS/MHz

■ JTAG

– IEEE 1149.1-1990 compatible Test Access Port (TAP) controller

– Four-bit Instruction Register (IR) chain for storing JTAG instructions

– IEEE standard instructions: BYPASS, IDCODE, SAMPLE/PRELOAD, EXTEST and INTEST

– ARM additional instructions: APACC, DPACC and ABORT

Integrated ARM Serial Wire Debug (SWD)

■ Internal Memory

– 64 KB single-cycle flash

• User-managed flash block protection on a 2-KB block basis

• User-managed flash data programming

• User-defined and managed flash-protection block

– 8 KB single-cycle SRAM

■ GPIOs

– 0-30 GPIOs, depending on configuration

– 5-V-tolerant in input configuration

– Programmable control for GPIO interrupts

• Interrupt generation masking

• Edge-triggered on rising, falling, or both

• Level-sensitive on High or Low values

– Bit masking in both read and write operations through address lines

– Can initiate an ADC sample sequence

– Pins configured as digital inputs are Schmitt-triggered.

– Programmable control for GPIO pad configuration

• Weak pull-up or pull-down resistors

• 2-mA, 4-mA, and 8-mA pad drive for digital communication

• Slew rate control for the 8-mA drive

• Open drain enables

• Digital input enables

■ General-Purpose Timers

– Three General-Purpose Timer Modules (GPTM), each of which provides two 16-bit timers/counters. Each GPTM can be configured to operate independently:

• As a single 32-bit timer

• As one 32-bit Real-Time Clock (RTC) to event capture

• For Pulse Width Modulation (PWM)

• To trigger analog-to-digital conversions

– 32-bit Timer modes

• Programmable one-shot timer

• Programmable periodic timer

• Real-Time Clock when using an external 32.768-KHz clock as the input

• User-enabled stalling when the controller asserts CPU Halt flag during debug

• ADC event trigger

– 16-bit Timer modes

• General-purpose timer function with an 8-bit prescaler (for one-shot and periodic modes

only)

• Programmable one-shot timer

• Programmable periodic timer

• User-enabled stalling when the controller asserts CPU Halt flag during debug

• ADC event trigger

– 16-bit Input Capture modes

• Input edge count capture

• Input edge time capture

– 16-bit PWM mode

• Simple PWM mode with software-programmable output inversion of the PWM signal

■ ARM FiRM-compliant Watchdog Timer

– 32-bit down counter with a programmable load register

– Separate watchdog clock with an enable

– Programmable interrupt generation logic with interrupt masking

– Lock register protection from runaway software

– Reset generation logic with an enable/disable

– User-enabled stalling when the controller asserts the CPU Halt flag during debug

■ ADC

– Six analog input channels

– Single-ended and differential-input configurations

On-chip internal temperature sensor

– Sample rate of one million samples/second

– Flexible, configurable analog-to-digital conversion

– Four programmable sample conversion sequences from one to eight entries long, with

corresponding conversion result FIFOs

– Flexible trigger control

• Controller (software)

• Timers

• Analog Comparators

• PWM

• GPIO

– Hardware averaging of up to 64 samples for improved accuracy

– Converter uses an internal 3-V reference

■ UART

– Two fully programmable 16C550-type UARTs

– Separate 16x8 transmit (TX) and receive (RX) FIFOs to reduce CPU interrupt service loading

– Programmable baud-rate generator allowing speeds up to 3.125 Mbps

– Programmable FIFO length, including 1-byte deep operation providing conventional

double-buffered interface

– FIFO trigger levels of 1/8, 1/4, 1/2, 3/4, and 7/8

– Standard asynchronous communication bits for start, stop, and parity

– Line-break generation and detection

– Fully programmable serial interface characteristics

• 5, 6, 7, or 8 data bits

• Even, odd, stick, or no-parity bit generation/detection

• 1 or 2 stop bit generation

■ Synchronous Serial Interface (SSI)

– Master or slave operation

– Programmable clock bit rate and prescale

Separate transmit and receive FIFOs, 16 bits wide, 8 locations deep

– Programmable interface operation for Freescale SPI, MICROWIRE, or Texas Instruments synchronous serial interfaces

– Programmable data frame size from 4 to 16 bits

– Internal loopback test mode for diagnostic/debug testing

■ Analog Comparators

– One integrated analog comparator

– Configurable for output to drive an output pin, generate an interrupt, or initiate an ADC sample sequence

– Compare external pin input to external pin input or to internal programmable voltage reference

– Compare a test voltage against any one of these voltages

• An individual external reference voltage

• A shared single external reference voltage

• A shared internal reference voltage

■ PWM

– Three PWM generator blocks, each with one 16-bit counter, two PWM comparators, a PWM signal generator, a dead-band generator, and an interrupt/ADC-trigger selector

– One fault input in hardware to promote low-latency shutdown

– One 16-bit counter

• Runs in Down or Up/Down mode

• Output frequency controlled by a 16-bit load value

• Load value updates can be synchronized

• Produces output signals at zero and load value

– Two PWM comparators

• Comparator value updates can be synchronized

• Produces output signals on match

– PWM generator

• Output PWM signal is constructed based on actions taken as a result of the counter and

PWM comparator output signals

• Produces two independent PWM signals

Dead-band generator

• Produces two PWM signals with programmable dead-band delays suitable for driving a

half-H bridge

• Can be bypassed, leaving input PWM signals unmodified

– Flexible output control block with PWM output enable of each PWM signal

• PWM output enable of each PWM signal

• Optional output inversion of each PWM signal (polarity control)

• Optional fault handling for each PWM signal

• Synchronization of timers in the PWM generator blocks

• Synchronization of timer/comparator updates across the PWM generator blocks

• Interrupt status summary of the PWM generator blocks

– Can initiate an ADC sample sequence

■ QEI

– Position integrator that tracks the encoder position

– Velocity capture using built-in timer

– The input frequency of the QEI inputs may be as high as 1/4 of the processor frequency (for example, 12.5 MHz for a 50-MHz system)

– Interrupt generation on:

• Index pulse

• Velocity-timer expiration

• Direction change

• Quadrature error detection

■ Power

– On-chip Low Drop-Out (LDO) voltage regulator, with programmable output user-adjustable from 2.25 V to 2.75 V

– Low-power options on controller: Sleep and Deep-sleep modes

– Low-power options for peripherals: software controls shutdown of individual peripherals

– User-enabled LDO unregulated voltage detection and automatic reset

– 3.3-V supply brown-out detection and reporting via interrupt or reset

■ Flexible Reset Sources

– Power-on reset (POR)

– Reset pin assertion

– Brown-out (BOR) detector alerts to system power drops

– Software reset

– Watchdog timer reset

– Internal low drop-out (LDO) regulator output goes unregulated

■ Industrial and extended temperature 48-pin RoHS-compliant LQFP package

■ Industrial and extended temperature 48-pin RoHS-compliant QFN package

LM3S818目标应用:

■ Factory automation and control

■ Industrial control power devices

■ Building and home automation

■ Stepper motors

■ Brushless DC motors

■ AC induction motors

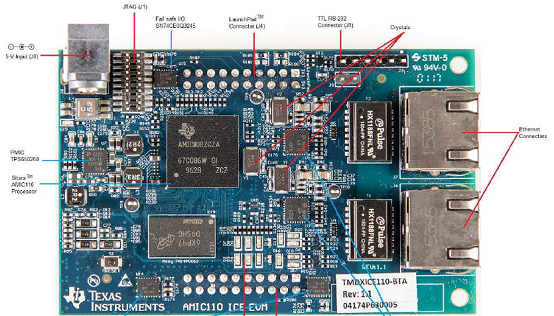

图1. Stellaris LM3S818 MCU方框图

图2. LM3S818控制器系统级框图

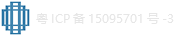

Stellaris® LM3S818 controlCARD模块

The Stellaris® LM3S818 controlCARD module is a DIMM form-factor module that can be used standalone or with a range of baseboards to accelerate evaluation and development.

Texas Instruments offers a range of controlCARD baseboards for motor and power-control application. In most cases. these are available as complete kits that include a controlCARD module and a baseboard. The Stellaris MDL-LM3S818CNCD is part of a controlCARD lineup that includes cards for C2000 and MSP430 devices.

图3. LM3S818 controlCARD三相BLDC马达模块外形图

LM3S818 controlCARD模块包括:

The LM3S818 controlCARD module kit comes with the following:

MDL-LM3S818CNCD controlCARD module

– On board Stellaris In-Circuit Debug Interface

Cables/Accessories

– USB-miniB to USB-A plug cable (for debug and serial communication)

– 1/2-inch blue jumper wires (for bridging power)

Development Kit CD containing:

– For the controlCARD module in standalone use:

• Complete documentation

• StellarisWare® Peripheral Driver Library and example source code

– For the controlCARD module when used with a supported baseboard:

• Source-code and binaries

• Documentation specific to each supported baseboard

• CrossHairs control GUI Windows application

Tools CD(s)

Texas Instruments’ Code Composer Studio™ IDE

Stellaris MDL-LM3S818CNCD controlCARD模块主要特性:

The Stellaris MDL-LM3S818CNCD controlCARD module includes the following features:

LM3S818IQN50 Stellaris microcontroller

– 32-bit ARM® Cortex™-M3 core

– 50 MHz max speed

– 64 KB Flash, 8 KB RAM

DIMM form-factor

GPIO signals available on DIMM edge-connector

User LED

Debug

– Stellaris In-Circuit Debug Interface (ICDI)

Isolated to 560 V working-voltage using Texas’Instruments’ digital isolators

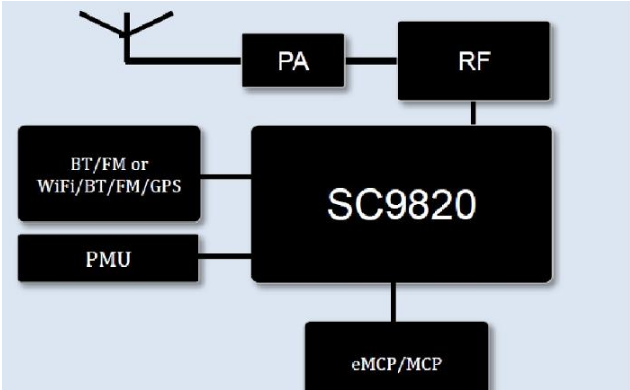

图4. LM3S818 controlCARD模块方框图

图5. LM3S818 controlCARD模块电路图(1)

图6. LM3S818 controlCARD模块电路图(2)

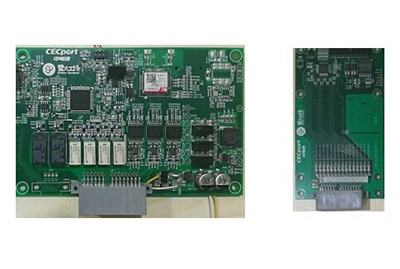

图7. LM3S818 controlCARD模块元件布局图:上图:顶层,下图:底层

责任编辑:HanFeng

【免责声明】

1、本文内容、数据、图表等来源于网络引用或其他公开资料,版权归属原作者、原发表出处。若版权所有方对本文的引用持有异议,请联系拍明芯城(marketing@iczoom.com),本方将及时处理。

2、本文的引用仅供读者交流学习使用,不涉及商业目的。

3、本文内容仅代表作者观点,拍明芯城不对内容的准确性、可靠性或完整性提供明示或暗示的保证。读者阅读本文后做出的决定或行为,是基于自主意愿和独立判断做出的,请读者明确相关结果。

4、如需转载本方拥有版权的文章,请联系拍明芯城(marketing@iczoom.com)注明“转载原因”。未经允许私自转载拍明芯城将保留追究其法律责任的权利。

拍明芯城拥有对此声明的最终解释权。

产品分类

产品分类

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)

2012- 2022 拍明芯城ICZOOM.com 版权所有 客服热线:400-693-8369 (9:00-18:00)